Key Words: LPBF, Design for AM, Topology Optimization, Bionics, Function Integration

Generative Design because New Manufacturing Methods Require New Designs

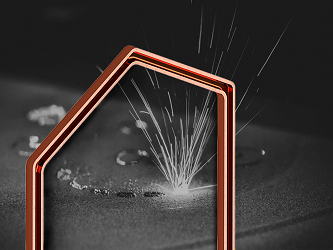

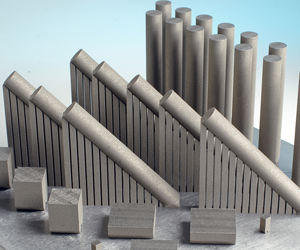

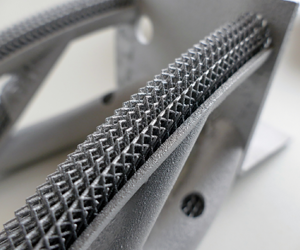

Applications in the function integration field, such as near-contour cooling systems, or lightweight structures, such as surfaceor grid-based structures, are also part of this design method. Despite the high geometric degrees of freedom in AM, in this case, there are also manufacturing restrictions which have to be considered by means of Generative Design algorithms.

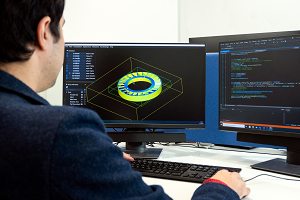

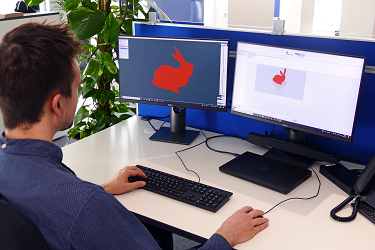

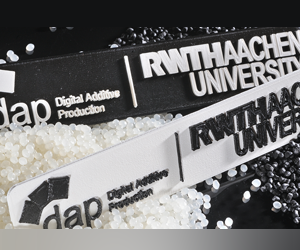

At the RWTH Aachen Chair for Digital Additive Production DAP different commercial software tools (Grasshopper, Siemens NX, 3DXpert, Netfabb) are available to support the design process optimized for AM. In addition, the Chair DAP develops customized solutions for computer-aided component design that can be integrated into existing software environments. A comprehensive database with material characteristics, production restrictions and process parameters is available for this purpose. We support you in the context of projects, training courses and software developments in the conception, design and subsequent production of innovative generative designs.

Johannes Willkomm, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Further Research Topics

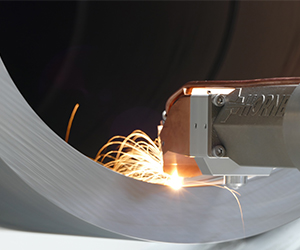

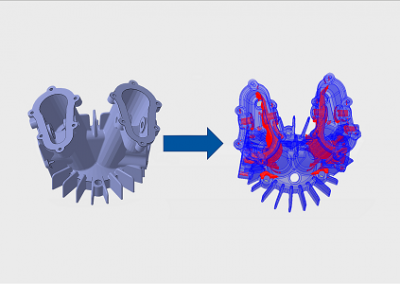

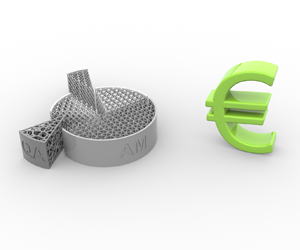

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.