Key Words: DfAM, Product Design, LPBF, Software

Design Wizard Enables Prediction about AM Part’s Quality

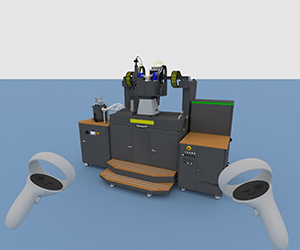

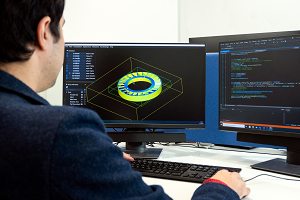

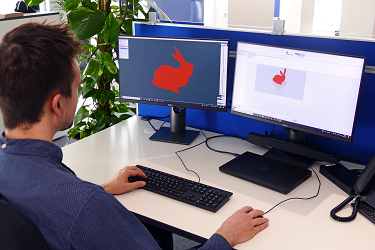

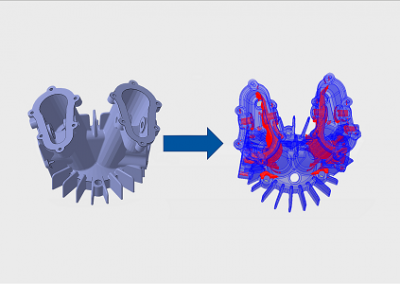

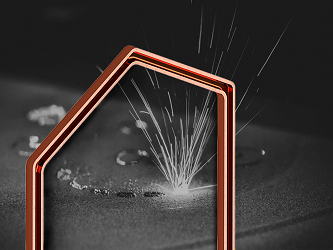

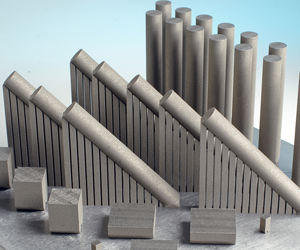

A key element in reducing the scrap rate in Additive Manufacturing (AM), especially of prototypes and one-offs, is a computer-aided design process that considers Laser Powder Bed Fusion (LPBF) specific design guidelines. The Design Wizard is a digital assistant developed at the DAP chair, which supports designers, engineers and every-one interested in 3D printing from the very beginning of the product development process and optimizes the design based on the applicable Design for Additive Manufacturing rules (DfAM). Surface roughness and mechanical properties of the final part are centered as the most important criteria in evaluating the quality of the part. However, this evaluation is usually done after production. It means that developing and improving a component design is very time consuming, since it can only be reviewed and adapted iteratively after the production process. Therefore, the main goal of the Design Wizard is to predict the quality of the part to be additively manufactured early in the (digital) design process and, if necessary, to revise it. Depending on the needs, other relevant factors like process parameters, orientation and position of the part can be optimized by the Design Wizard, too.

Amin Rahmati, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Further Research Topics

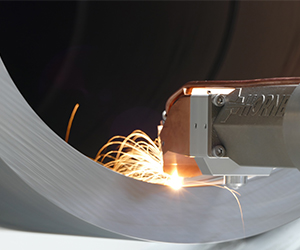

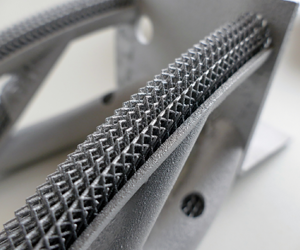

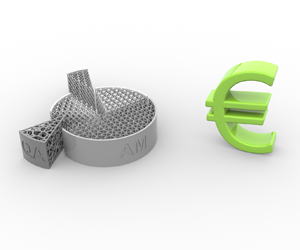

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.