Shape the Future,

Enter the Additive Manufacturing World!

Would you like to specialize in a future-oriented topic? Join us in researching into Additive Manufacturing and Digitalization: for example, as part of a lecture, a thesis or as a research assistant!

Do you have questions regarding teaching, our lectures or exercises?

Contact us at lehre@dap.rwth-aachen.de

Our Lectures

The course will teach you the individual elements of the entire AM process chain and everything about how metal-based and polymer-based AM processes work. Additionally, you will expand your knowledge base to include the topics of processable materials as well as process development and monitoring. Furthermore, you will discuss design limits. Completing the course, you will be able to design production-ready components autonomously.

The course contents will be deepened in exercises and tangible within a laboratory tour.

These processes will be discussed during the lecture:

- Laser Powder Bed Fusion (LPBF)

- Laser Metal Deposition (LMD)

- Fused Filament Fabrication (FFF)

- Selective Laser Sintering (SLS)

- Stereolithography

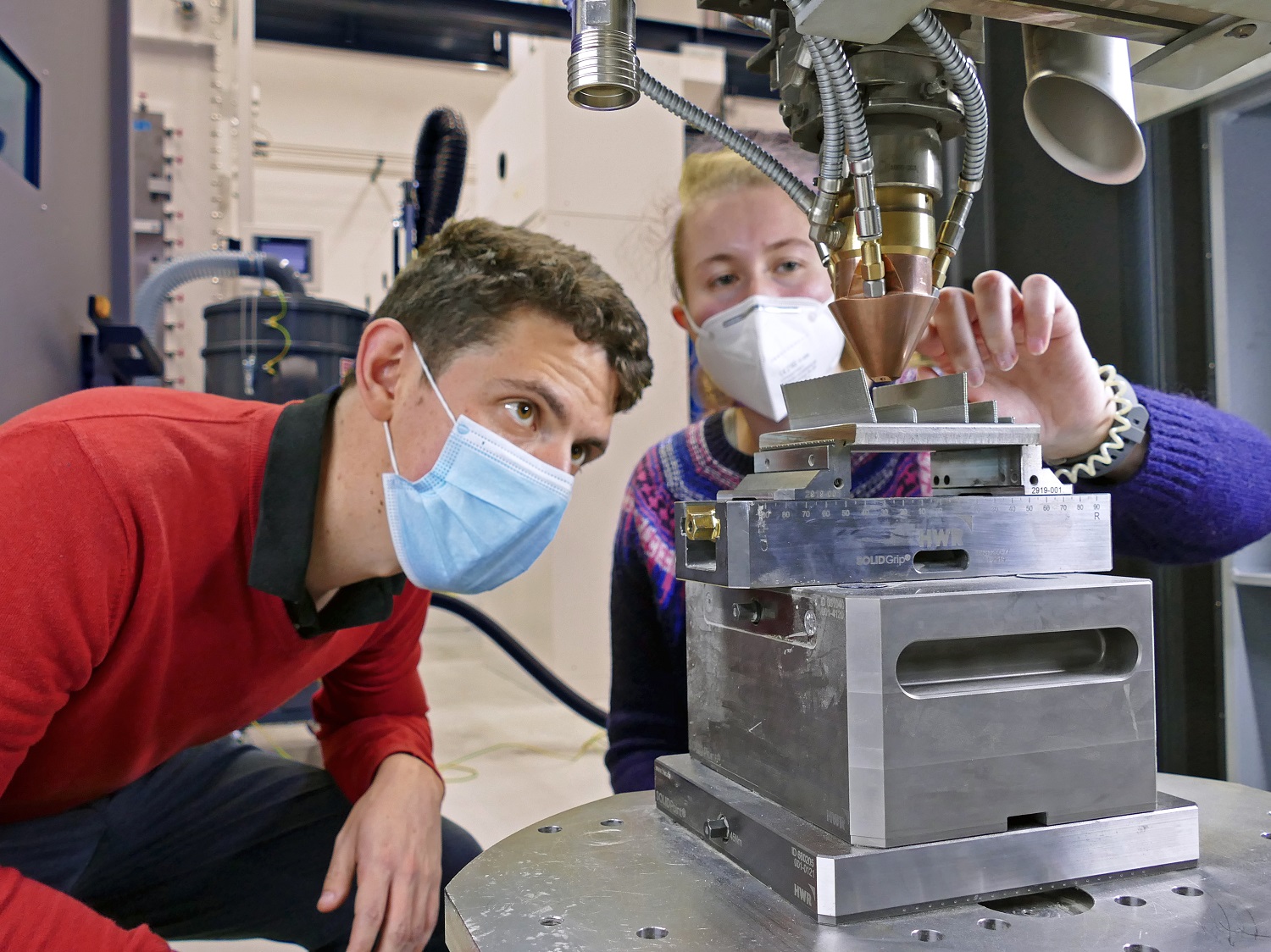

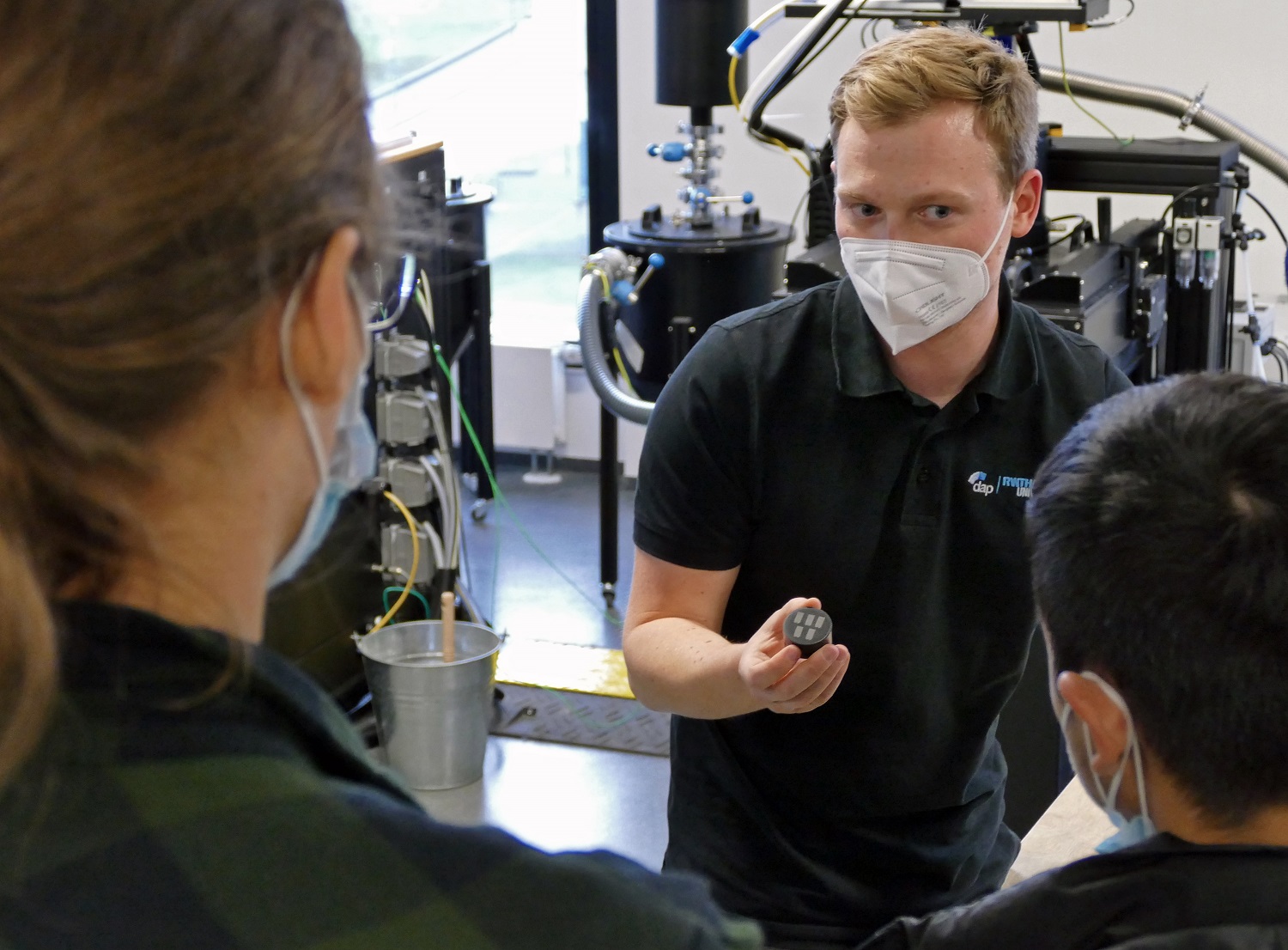

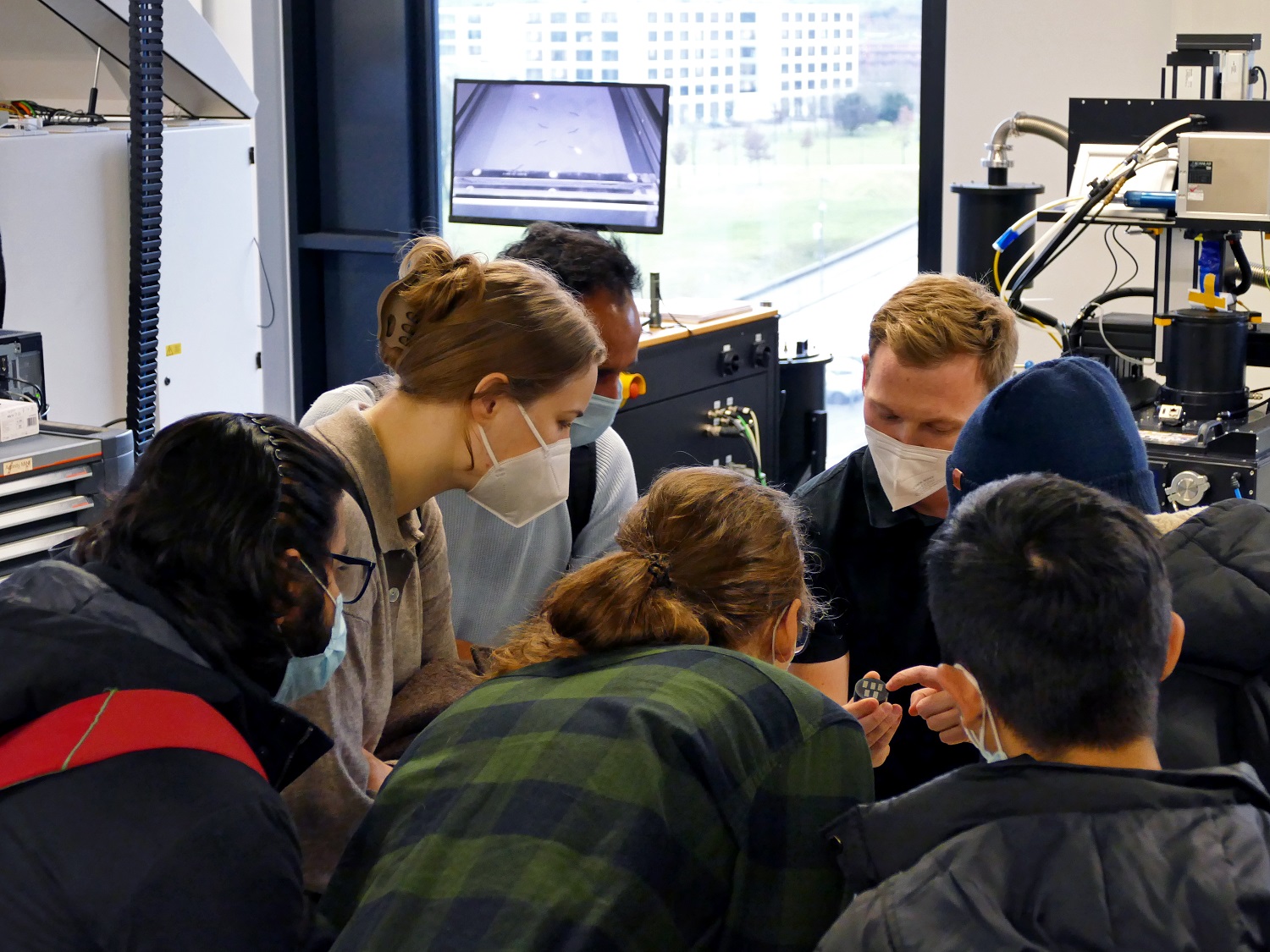

Insights into the Lab Tour as Part of the AM I Lecture

Participating in the new lecture “Additive Manufacturing Processes: Engineering and Design” (AM II), you will round off your knowledge about the Additive Manufacturing technology. You will learn more about development and design methodology as well as business organization topics. With regard to the AM product development process, you will discuss classical as well as novel approaches such as VDI2221, SCRUM or Agile Product Development. Subsequently, you will learn more about design rules as well as methods to be considered in AM component design. These include function integration, topology optimization and lattice structures. At the end of the lecture, you will acquire approaches for evaluating business cases and learn more about the classification of business organization tools such as PLM and ERP.

At the beginning of the reverse engineering process, existing components have to be measured. Serving as a basis, CAD models are derived from this measurement data. Reverse engineering in combination with Additive Manufacturing processes is used, for example, to produce spare parts for components whose raw data is no longer available. In medical technology, for instance, reverse engineering can be used to create patient-specific implants or orthoses. The required precise models can be generated quickly using fringe light scanners. However, the data often needs to be reworked. No news for you after this MTL!

Here’s what you’ll do in this lab:

- Learn the principles of 3D scanning

- Scan an object autonomously with an industrial scanning system (fringe light scanner)

- Create a program for post-processing point clouds and generating STL files based on a C++ library

- Become familiar with the challenges of creating and processing models generated with a 3D scanner

Polymer-based Additive Manufacturing processes, such as Multi Jet Fusion (MJF), are already being used profitably in large-scale production. As a raw material, Polymer powder is used in many Additive Manufacturing technologies, including MJF. This powder can be applied both locally and globally, and, thus, can be fused or sintered layer by layer to form a component.

This MTL will focus on the powder bed-based MJF process. During the process the the polymer powder is applied layer-by-layer and remains in the build space. Throughout the building time, the powder is exposed to a wide variety of influences, e.g. temperatures up to about 185 °C. As a result, aging of the polymer powder occurs, which affects the resulting component quality. It can lead to a deterioration of the surface quality as well as to a reduction of the achievable mechanical properties.

Here’s what you’ll do in this lab:

- Become familiar with the MJF equipment and the MJF process

- View and measure different stages of powder aging

- Based on this, evaluate at which aging stage a powder is no longer usable

- Determine at which stage it has a significant impact on component quality

- Apply different powder analysis methods

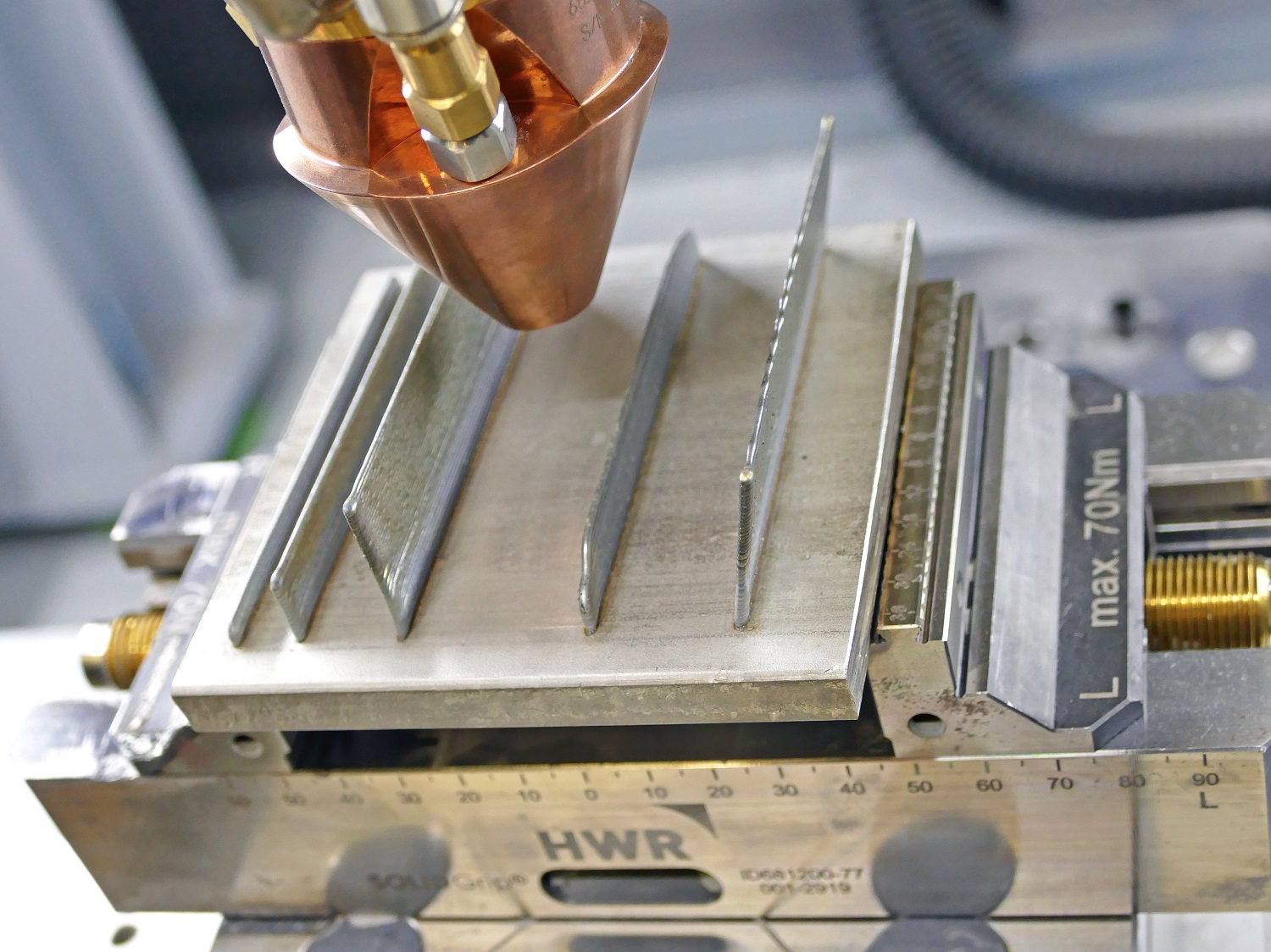

For the first time, highly complex lattice structures that, for example, can be used in lightweight construction applications, can be (economically) manufactured through Additive Manufacturing. Lattice structures are very fine geometries, with strut diameters of < 300 µm. For this reason, the fabrication of such geometries requires particularly high resolution and accuracy. In this MTL, we will focus on the entire process chain of Laser Powder Bed Fusion (LPBF), a metal powder bed-based 3D printing process. The powdery material has powder particle sizes of approximately 15 – 45 µm.

During the subsequent melting of the powder material by means of laser radiation, deviations from the computer-generated target CAD geometry naturally occur. This deviation essentially results from the melt pool formation and size, which depends on a wide variety of influencing factors.

Here’s what you’ll do in this lab:

- Gain a basic understanding of AM, with a focus on metal materials

- Go through the entire LPBF process chain using the example of lattice structure manufacturing

- Acquire a deeper understanding of the entire LPBF process chain:

- CAD file

- Manufacturing process

- Quality assurance

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.