We are your enabler and companion

Let’s Make Your Company Future-Proof and Innovative Together!

We see ourselves as an innovation driver and enabler. Our goal is to profitably implement digitalization and Additive Manufacturing into the value chains of the manufacturing industry – for example, in the automotive sector, medical technology or even at a household appliance manufacturer. Almost every industry can increase its potential through the use of digital and Additive Manufacturing technologies. Join us on the road to the industry of the future and drive your digitalization and AM topics forward together with us!

From production digitalization and networking to material development and component manufacturing to post-processing and quality assurance: We accompany you from the first idea to the final product – contact us!

Our Service Portfolio for the Development of Your Solutions

Unleash the Potential of Your Production!

Digitalization and novel manufacturing technologies, such as Additive Manufacturing, demand a transformation of existing production chains: This applies to data creation and preparation, manufacturing as well as post-processing. We support you to transfer of your conventional manufacturing technologies to Digital Additive Manufacturing.

For the design of your production we offer:

- Process chain evaluation

- Design for Manufacturing, i.e. Tooling

- Production optimization of your components: from design to orientations to machine settings

- Targeted literature research with derivation of recommendations

- Process, equipment and material qualification

- Preparation of production data

- Joint development of the process route

- Business case evaluation, i.e.

- Reliable cost calculation of the manufacturing process

- Part Identification: Identification of potentials in your company

Remote and Traceable: Digital Production as a Quality Guarantor.

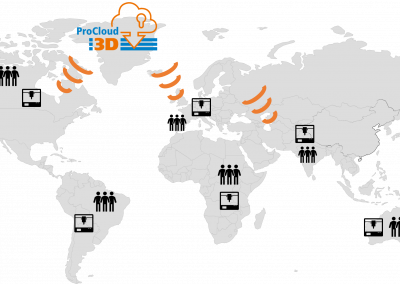

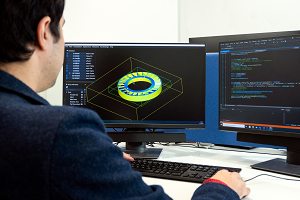

As a digital manufacturing technology, Additive Manufacturing is closely related to process prediction and process monitoring, enabling location-independent, resilient production. Join us in creating your digital production network.

For the digitalization of your production, we offer:

- Solutions for continuous and loss-free data transfer (CAD / CAM) along the digital process chain.

- Machine-adapted preparation of production data (keyword: machine transferability)

- Statistical and AI-driven evaluations with Big Data

- Predictive Process, Maintenance and Quality

- Innovative in-line process monitoring

Customized Components for Your Application

Whether material properties or geometry – Additive Manufacturing allows components to be customized to your application. It can even offer solutions that have not been thought of before. More efficient, sustainable and resource-saving – your use case has the potential!

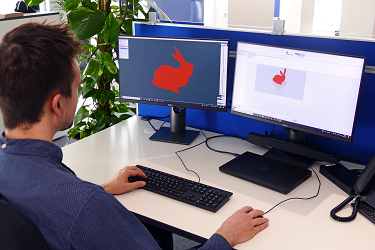

For rethinking your products, we offer:

- Part Identification: Identification of potentials in your company

- Generative Design: Optimization of part geometry

- Reverse Engineering

- Preparation of manufacturing data

- Targeted literature research with derivation of recommendations

- Software for design automation

- Component evaluation: assessment with regard to feasibility and manufacturing processes

- Component analysis: this includes relative component density, mechanical properties, geometry mapping, chemical composition, etc.

- Functional prototyping: production of prototypes including functional integration

- Design of existing components for Additive Manufacturing: e.g. design adaptation

- Post-processing by means of vibratory grinding, pressure flow lapping, sandblasting, heat treatment, etc.

- Quality assurance using materialography, testing machines, 3D scanners, X-ray fluorescence spectrometers, etc.

- Multiphysical topology optimization

- Digital materials for component adaptation to subsequent application, e.g. load-adapted support structures

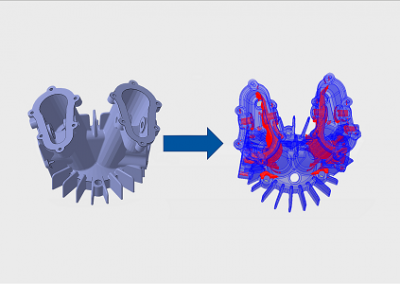

- Predictive warpage simulation to reduce the resulting warpage

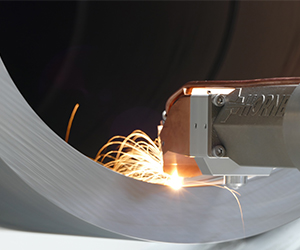

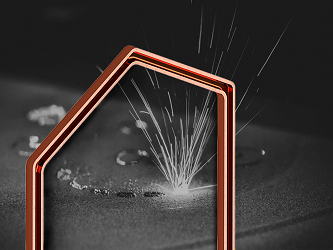

Master Your Manufacturing Process

The various manufacturing processes of the Additive Manufacturing Technology follow their own rules and often deviate from proven experience. Once you have mastered them, the path is clear to advance and realize digital ideas.

Transfer your ideas into the physical world together with us!

For the development of materials and your process, we offer:

- Definition and identification of relevant process influencing factors

- Process-optimized component design

- Preparation of manufacturing data

- Process simulation

- Consideration of the process heat balance in the customer-specific component

- Simulation-based defect analysis

- Literature research with evaluation of data

- Material development and qualification

- Feasibility studies

- Machine characterization: laser beam source, protective gas flow and powder deposition quality.

- Development of the process route in cooperation with the customer (if necessary on site)

- Quality assurance using e.g. materialography, testing machines, 3D scanner, X-ray fluorescence spectrometer

Make Your Employees Ready for Additive Manufacturing

Proven know-how is not to be underestimated – but it always needs an update with regard to the implementation of new technologies. You want to make your employees ready for Additive Manufacturing? We offer the necessary update!

For the know-how update, we offer:

- Workshops around product and production digitization as well as additive manufacturing process chain

- Modeling workshop

- Development of customized training solutions for your employees, e.g. for process set-up, parameter variation for process adaptation, machine set-up

- On-site commissioning

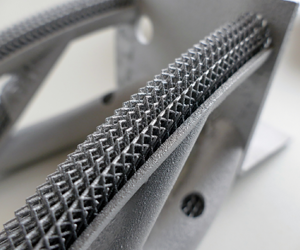

Previous Research

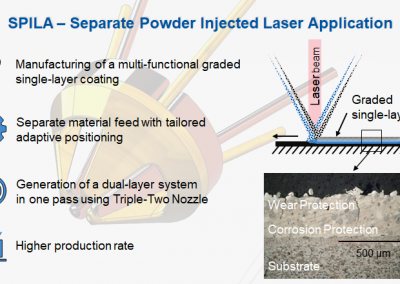

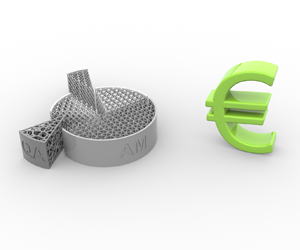

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.