Keywords: Cloud, Streaming, Data Security, Digitalization

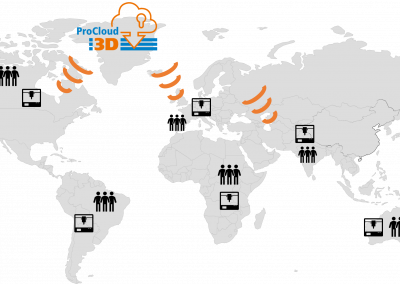

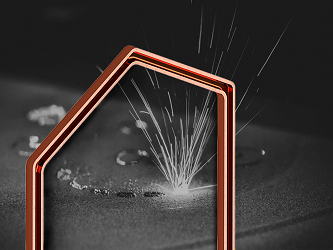

ProCloud3D for secure on-demand manufacturing

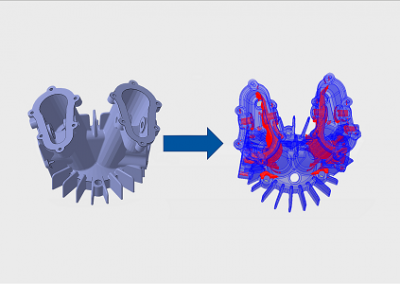

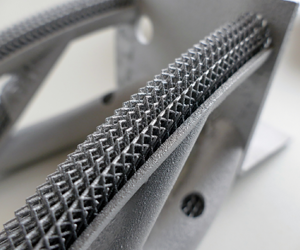

Additive Manufacturing (also: 3D printing, AM) enables manufacturing companies to react quickly to changes in global competition. From the end user’s point of view, the design data of 3D-printed components is particularly worthy of protection, since a significant proportion of the added value is already created in the design of the components. If the service provider knows the relevant material-specific process parameters, the manufacturing process itself is merely an enabling function, which reduces the depth of added value in this process step. Up to now, the component data for 3D printing has been sent digitally to the manufacturer, usually an external service provider. The latter is then responsible for the process of so-called data preparation, i.e. the compilation of several components into a production order as well as the corresponding further processing and preparation for the printing process. Even with secure transmission, it is possible that the data could be compromised or used for unauthorized production of similar parts. Since all steps from the design to the production of the components are extremely knowledge-intensive, the required respective know-how along the process chain serves as a unique selling point for the end customer, equipment manufacturer and service provider and is accordingly worth protecting.

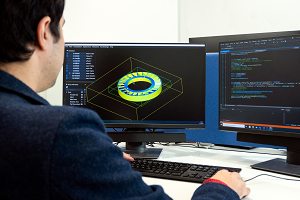

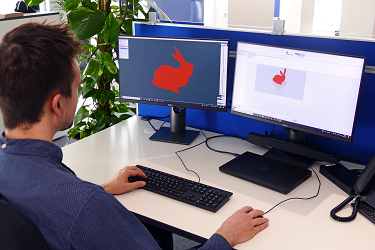

The project aims to develop and test a cloud-based platform on which all steps for preparing and carrying out the 3D printing process are mapped in a decentralized and encrypted manner with the participation of equipment and software manufacturers as well as research institutions from both nations. The project will be accompanied by efforts to standardize the developed interface and the underlying encryption technologies. The project results are to be transferred to a demonstrator in both countries at the end of the project.

Following the objectives, a novel platform will be developed which generates the production data layer by layer and based on material-specific process parameters stored in a technology database. The data is then transferred to the 3D printer in a protected manner. The generated layer data must be prepared in such a way that it can be made available to various 3D printers, including higher-level security infrastructures. This creates a protected value chain whose overarching license management authorizes, manages and controls all the necessary data transfer and process steps between the parties involved. Finally, two national demonstrators will show how end customers can have components manufactured by service providers using Additive Manufacturing while safeguarding their corporate interests and unique selling points.

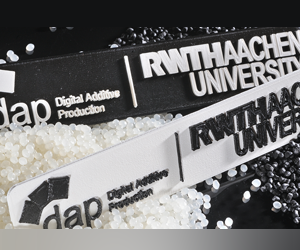

Moritz Kolter, M. Sc.

RWTH Aachen University Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen