Key Words: LPBF, Production Planning, Build Time Calculation, Economic Efficiency

Innovative and Reliable Cost Calculation Tool for Modular Laser Powder Bed Machine Concepts

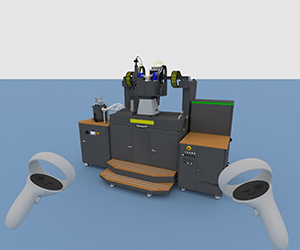

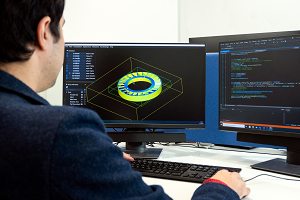

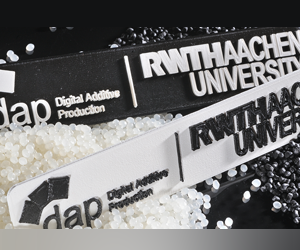

The RWTH Aachen University Chair for Digital Additive Production DAP has recently developed an innovative and reliable LPBF cost calculation tool for these modular system solutions: the virtual module emulator that is integrated into the entire digital LPBF process chain. The virtual module emulator replaces the real machine by processing the layered 2,5D geometry data and by virtually executing the contained scanning vectors. A procedural control, implemented by individual module instances in a service-oriented architecture (SOA), executes the LPBF process by calling virtual services, e.g. the virtual “coater” that executes the action “add powder”.

The cost calcualtion tool allows for optimized production planning and machine utilization since an almost exact build time calculation predicts when the machine operator has to take action, for instance. Additionally, the calculation accuracy enables both system suppliers as well as system operators to make dependable statements regarding economic efficiency and required degree of system modularity for an optimal production of customized componens.

Sebastian Dirks, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Further Research Topics

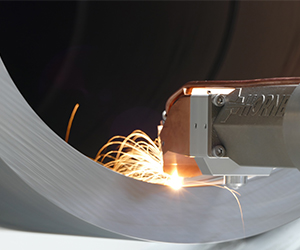

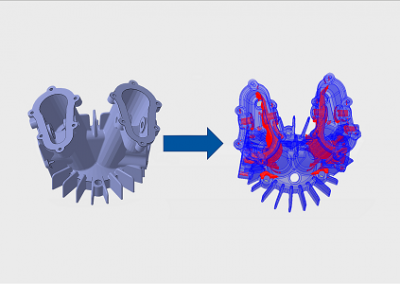

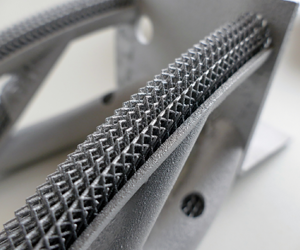

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.