Key Words: LPBF, AM Materials, Alloy Development, Multidimensional Design, HEA

Rapid Alloy Development Using AM: Advanced Materials Optimized for AM Processing and Applications

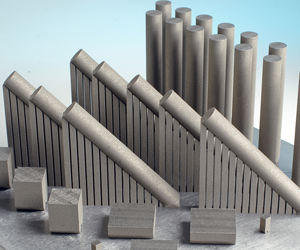

Rapid Alloy Development (RAD) is an approach for time- and cost-efficient development of alloys using Additive Manufacturing (AM) processes. Usually, the development of new alloys requires time-consuming and energy-intensive processes to produce small melts on a laboratory scale. Using these alloys, test specimens are produced by conventional manufacturing processes, which are then examined with regard to their properties (mechanical, physical, etc.). This process is repeated iteratively until an alloy composition has been determined which meets the required profile. It is possible to develop alloys more efficiently in terms of time and costs utilizing powder-based AM processes. The powder-based process is the key-enabler for RAD. At first, homogeneous blends of elementary powders are produced, which are then processed by means of AM processes, enabling the direct production of test specimens (cubes, tensile, lattice, etc.) from powder blends.

Time-consuming and cost-intensive laboratory melts and sample production in conventional manufacturing processes are thus eliminated. Therefore, the production and characterization of a large number of specimens with varying alloy compositions within a very short period of time becomes feasible and, even more important, economically viable. Furthermore, the approach fosters the understanding of new alloy systems, so that compositions which are created by means of RAD and processed by means of AM are superior to conventional alloy development approaches. The Chair for Digital Additive Production DAP relies on vast know-how and cooperations in the area of metal alloy development. To cover the entire process chain of RAD at the RWTH Aachen Campus, the Chair DAP has access to powder atomizing facilities, metallurgical equipment, test benches and a unique AM system technology.

Simon Ewald, M. Sc., IWE

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Further Research Topics

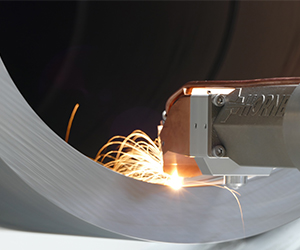

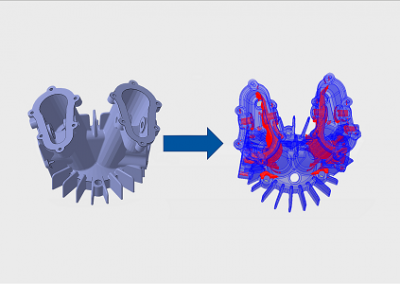

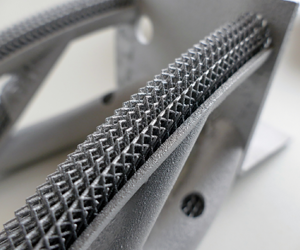

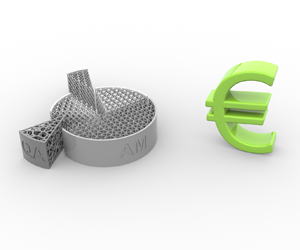

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.