Key Words: Part Identification, AM-Implementation, AI

Selection of Parts for AM Using Efficient

Algorithms and Logics

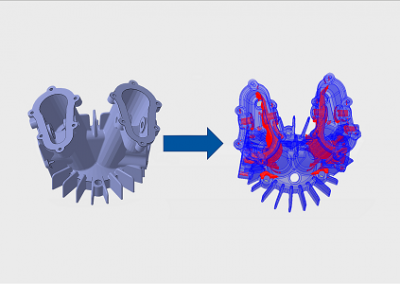

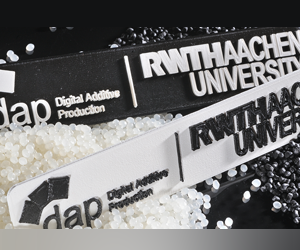

Additive Manufacturing (AM) offers numerous advantages over conventional manufacturing processes. Nevertheless, the use of this manufacturing technology is not suitable for every component: especially the currently high production costs make it difficult to use the technology in an economically viable way. Therefore, an important factor influencing the profitable use of AM is the selection of suitable components. This selection often challenges companies since technical, economic and strategic aspects have to be considered and weighed each other at the same time. For this reason, the full potential of AM implementation remains unrecognized due to a lack of know-how, high manual efforts in data procurement and complex component portfolios. In this regard, the DAP chair develops automated approaches for selecting AM-suitable components to enable companies to focus their resources on the components and assemblies that offer the greatest AM potential.

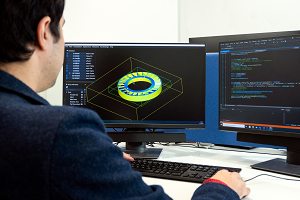

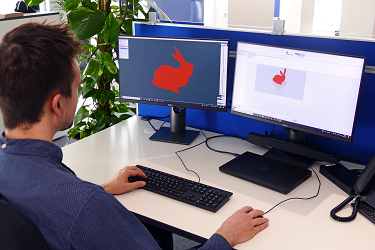

to focus their resources on the components and assemblies that offer the greatest AM potential. This includes, among other things, a key performance indicator system and an AI-based potential assessment: components can be assessed in terms of their technical suitability through an automated analysis of the geometry. more, key figures based on ERP data are to estimate the economic efficiency. The strategic use of AM in applications where massive advantages exist over conventional manufacturing can, thus, be systematized and facilitated. In addition, the DAP chair identifies AM-suitable components using a semi-automated screening approach. This way, the chair already supports companies with little experience in AM as well as companies with an existing additive production in developing their AM potential.

Moritz Kolter, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Further Research Topics

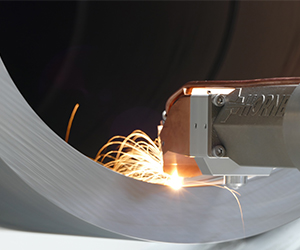

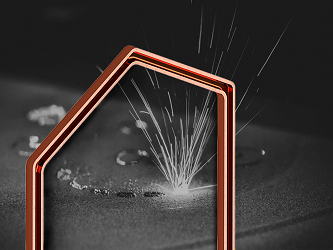

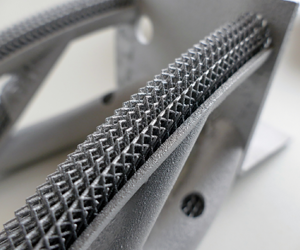

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.