Keywords: materials, Spila, coating, multi layers

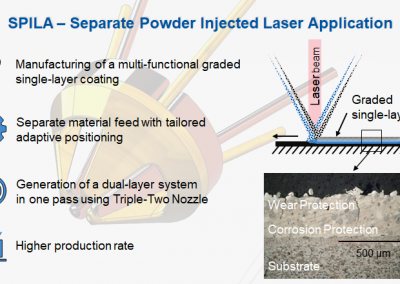

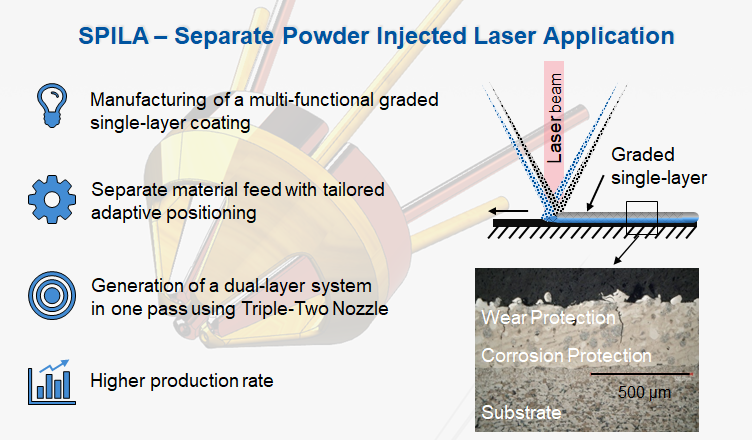

DAP Chair and HD Sonderoptiken für die Lasertechnik GmbH & Co. KG join forces in the development of Separate Powder Injected Laser Application (SPILA) for multi-functional graded single-layer coating

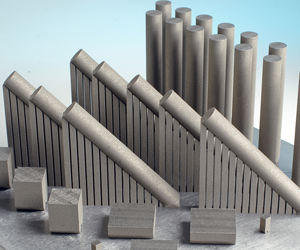

Today, the demands on components and surfaces are constantly growing and more complex challenges must be dealt with. In order to meet growing requirements, powder blends are increasingly being used. Thereby, the individual powder material properties differ in terms of morphology, degree of absorption, melting temperature and other material properties. SPILA – Separate Powder Injected Laser Application provides the capability to individually adjust the supplied materials and hence to generate tailored layers.

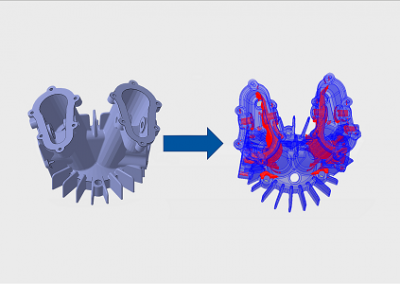

Nowadays requirements, such as tribological properties as well as wear and corrosion resistance, are constantly increasing and are often only achievable using powder blends or multi-layer systems. The challenge with prior mixed powder blends is usually a trade-off between the respective properties of the materials as well as their processability in terms of process parameters, morphology and thermal behavior. Using multi-layer systems made of different materials these challenges can be reduced, however, for each functionality a separate time-consuming layer is required. For example, the combined corrosion and wear protection can be named.

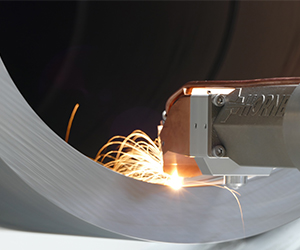

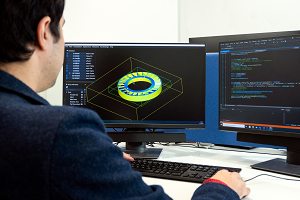

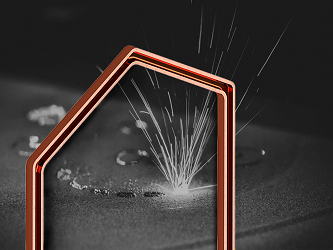

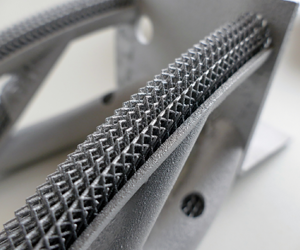

Using Separate Powder Injected Laser Application (SPILA), developed by the DAP Chair and HD Sonderoptiken fuer die Lasertechnik GmbH & Co. KG, allows a tailored adapted approach to individual materials and to improve productivity through direct graded single-layer coatings. Due to the separate adaptive material supply, the powders are individually injected to the process, allowing a tailored Laser-Material interaction. This enables the heating of the powder to be specifically adjusted by process parameters as well as the relative position of the powder feeds to each other. These new possibilities allow the layer composition to be controlled to enable a new dimension in the manufacturing of coatings.

For the processing of two powders, the Triple-Two Powder Nozzle has been developed. Two separate powder gas streams with adjustable relative positions to each other are used to feed the two materials. This allows, for example, a multi-functional graded single-layer coating to be produced. Using a relative shift of the powder focus perpendicular to the laser beam, a two-layer system for combined corrosion and wear protection, which usually requires two passes, can be replaced by a graded single-layer system. However, this innovation can improve the efficiency of processes due to reduced coating times.

Overall, the application of SPILA offers a wide range of new possibilities for the tailored composition of generated layers. However, there is a new technological solution available with SPILA to meet the increasing complexity of requirements and higher production rates.

Stephan Koß, M. Sc.

RWTH Aachen University Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen