Key Words: LPBF, EBM, FDM, Software, Digital Process Chain, Testing Environment

Digital Additive Enterprise: Software Sandbox Provides a Unique Testing Environment for AM Chains

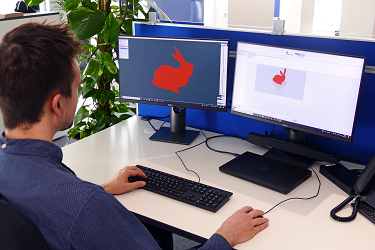

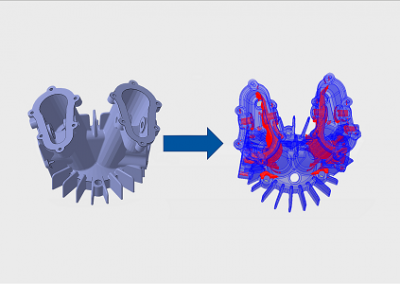

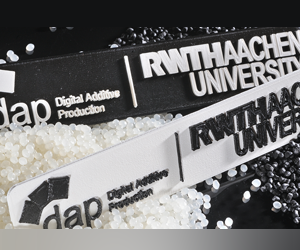

Additive Manufacturing (AM) offers new opportunities in digital end-to-end processes and, compared to traditional manufacturing techniques, is one of the readily available digitalization branches. The direct and fast transfer of digital model geometries into real parts is linked vertically (upstream) with enterprise-class Product Lifecycle Management (PLM) systems and Manufacturing Execution Systems (MES). Parts are linked directly with digital product data (downstream). The Chair DAP´s vision of a Digital Additive Enterprise includes multiple software solutions meshed together forming a perfectly working universal part factory. In contrast, the current state-of-the-art is characterized by a broad spectrum of different data interchange formats, stand-alone software and digital break points, resulting in a variety of possible combinations, data loss and inefficiencies along the digital process chain. To streamline the information flow from designer, to machine, to end-customer and to develop new digital solutions for enterprise manufacturing systems, the RWTH Aachen Chair for Digital Additive Production DAP recently initiated a “Software Sandbox” approach, continuously integrating all recent and advanced software solutions that are applied in the AM industry into this sandbox.

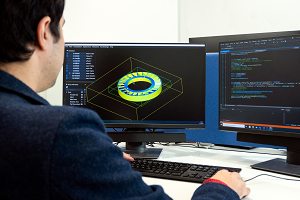

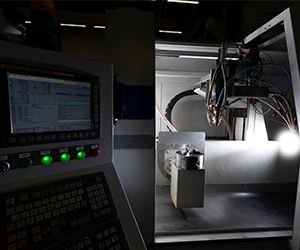

This sandbox serves as a unique testing environment, giving industrial as well as R&D partners the opportunity to test digital solutions without constraints resulting from an operating production environment. Powerful industry grade software like Siemens NX (CAD), Siemens Teamcenter (PLM) and Link3D’s Additive MES Software solution combined with access to industrial LPBF, EBM and FDM machines enable the proof of viability of next-generation digital solutions in an enterprise-class test environment.

All steps of the process chain can be benchmarked and tweaked to fit individual needs and use cases of different industries like automobile, turbomachinery, medical or spare part production. The broad AM know-how of the Chair DAP and its research partners at the RWTH Aachen Campus is, thus, transformed into holistic and advanced AM software solutions.

Sebastian Dirks, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Further Research Topics

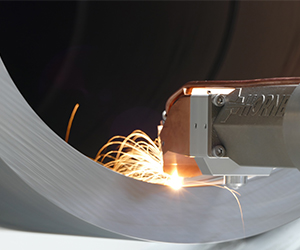

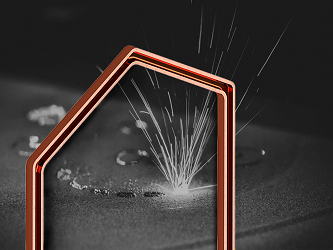

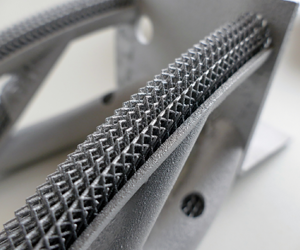

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.