Key Words: LPBF, Simulation, Cooling Rates, Temperature Profile, Mechanical Properties, Structural Analysis

Simulation of the LPBF Process: Insights into Melt Pool Geometry and Thermal History

From process parameters, to temperature profile, to microstructure and effective mechanical properties: With the rise of Additive Manufacturing (AM) processes, we need to gain a greater insight into a lot of well-known materials (from other processing routes) regarding their mechanical properties.

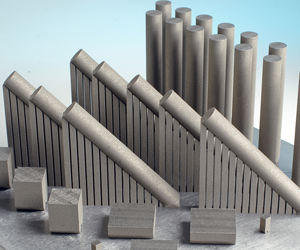

In established processes, like casting, the cooling rates are typically low (10. K/s) and the resulting microstructure as well as the mechanical properties are typically well known. For the Laser Powder Bed Fusion process (LPBF) the cooling rates are high (up to 107 K/s) and the mechanical properties anisotropic due to the energetically favorable grain growth in build-direction. Since the cooling rate at the phase front (liquid to solid) cannot be directly observed, it is crucial to model the solidification process taking the relevant physical phenomena into account.

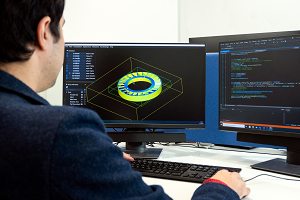

The RWTH Aachen Chair for Digital Additive Production DAP developed a model for calculating the melt pool geometry and thermal history for the LPBF process dependent on the process parameters for different materials. First comparisons of the simulation results and the experimentally obtained melt pool geometries have shown deviations < 10 % for Inconel 718, varying laser power and scan speed.

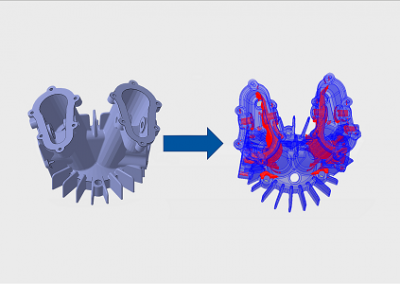

The cooling rate serves as input for the phase-field simulation with MICRESS from ACCESS e.V. which is used to simulate the grain growth in 3D (for a small region). Different grain growth directions directly compete against each other. The simulation duplicates the grain size and the preferred growth direction that are found in experimental investigations. The remaining challenge lies in the determination and verification of effective material properties from the heterogeneous LPBF manufactured material. The overarching goal is to control the grain size and the segregated phases during the solidification process by specifically choosing the process parameters and the material to obtain the desired mechanical properties for the designed part. The acquired process understanding can help signifcantly to develop new LPBF specific alloys.

Jonas Zielinski, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Further Research Topics

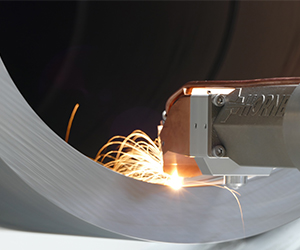

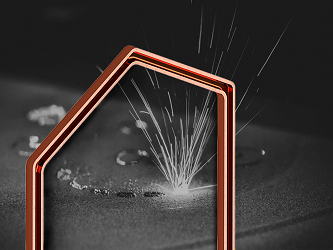

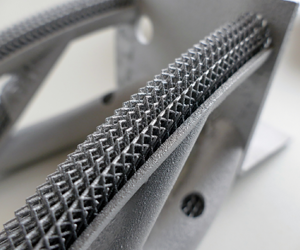

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.