Key Words: LPBF, VIRTUAL REALITY, EDUCATION, REMOTE, NEW WORK

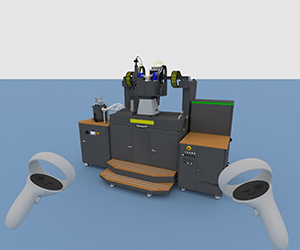

Digital Education: Virtual Reality LPBF Training

One of the biggest obstacles that is yet to overcome for the implementation of Additive Manufacturing (AM) is the lack of capability and know-how. It is shown that the rapid technological development urges effective, scalable and up-to-date AM training programs using new learning methods, tools and technologies. In addition, the Corona pandemic demonstrated the need for new forms of work and emphasized the importance of remote training to tackle the challenging future of work.

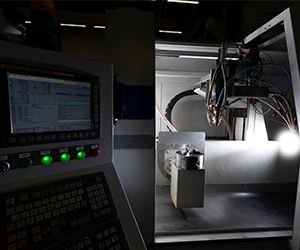

In this regard, the DAP chair develops new learning methods in the field of AM in close collaboration with industrial partners. The first of this series of innovative trainings uses Virtual Reality (VR) to train employees to operate an industrial LPBF machine.

Machine operators, who either come from traditional manufacturing (like CNC milling) or need to learn the handling of a new LPBF machine, can take advantage of joining a training session remotely via VR.

The training in VR covers the key aspect of the operation of a LPBF machine and, as reference, it uses the qualification principles from ISO/ASTM 52942:2020 — Qualifying machine operators of laser metal powder bed fusion machines and equipment used in aerospace applications. By means of VR training, the machine operators can accelerate their learning curve and minimize operation errors. Furthermore, this innovative training using VR supports upskilling and reskilling of workforce remotly and in a scalable way.

The capability of companies to actively react to digitalization is a main factor in competitiveness. Lifelong learning via corporate professional programs is one of the key measures to face this challenge. For this reason, the DAP chair develops further virtual training solutions to ensure to get the industries’ workforce prepared for the present and future of Additive Manufacturing.

Gustavo Melo, M. Eng.

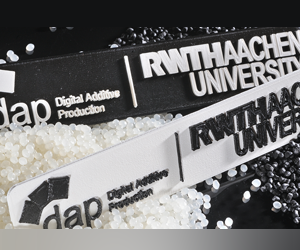

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

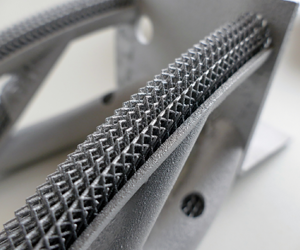

Further Research Topics

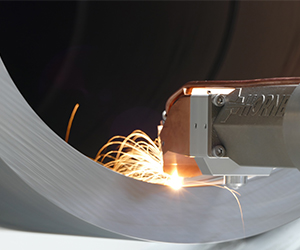

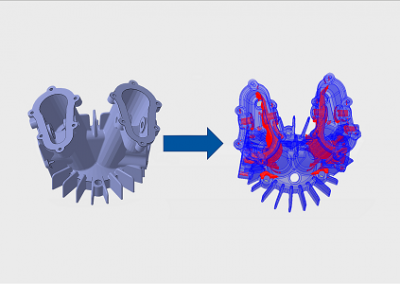

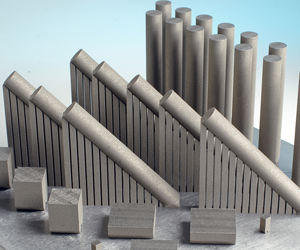

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.