Key Words: LPBF, Life Sciences, Bioresorbable, intelligent lattice structures

Algortihmic Design of Lattice Structures for Bioresorbable Zn-Mg Alloy Implants

Medical implants are often used to replace missing body parts or to provide support for organs and tissues. For the latter application, bioresorbable implants may be used, an example of which is bone grafting to repair a critical bone defect with a size > 20 mm. These implants degrade in the body over time and do not require an implant-removal surgery. The materials used for this purpose are, among others, bioresorbable and biocompatible Zinc (Zn) and Magnesium (Mg) alloys because of their mechanical properties close to the body bones and their high biocompatibility. Those materials can be tuned with respect to the required mechanical and corrosive behavior of implants. For example Zn1Mg alloy, developed at the DAP chair, shows a promising behavior to be used as implant materials.

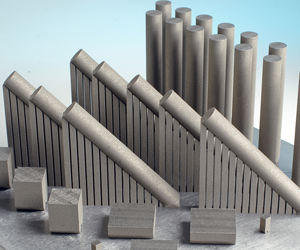

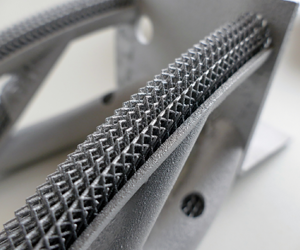

Additive Manufacturing, particularly Laser Powder Bed Fusion (LPBF), is an enabler to process those bioresorbable and biocompatible alloys to produce patient-specific and optimized structures, like spongy and porous trabecular bone tissue replacements. The bone implant is designed as lattice structures that are optimized not only to the production process constraints but also to the requirements regarding the bioprocesses in the body.

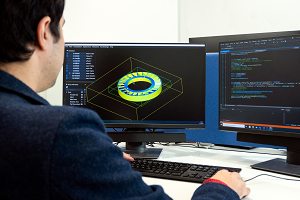

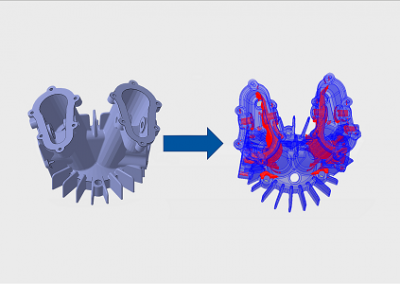

At the DAP chair an algorithmic lattice structure generation tool for modeling and modification of lattices has been developed that automatically includes all the requirements, hence, accelerating and optimizing the design process and the product compatibility. It includes two databases with material processability information and biological patient-specific data: On the production side, the generated lattices consider critical overhang angle, minimum producible feature size and minimum distance between design features. Since biomolecules and biological liquids interact with implants and differ according to e.g. gender, the information of the corrosive behavior of patient bodies is also considered. This way, strut diameters of lattice-structured implants are adapted to the required degradability. In addition, lattice structures can be designed in a (semi-)geometry-adapted manner. LPBF fabrication of the generated lattice structures has been validated for the Zn1Mg alloy and a reproducible strut diameter of 200 µm and a relative density > 99,5% were achieved.

Maximilian Voshage, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Omid Zarei, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Further Research Topics

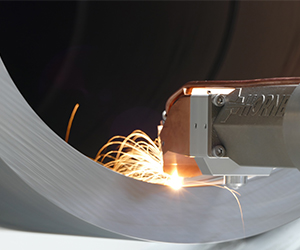

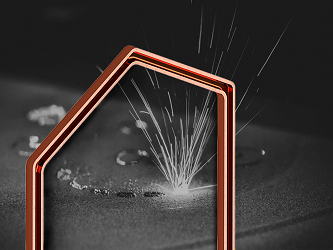

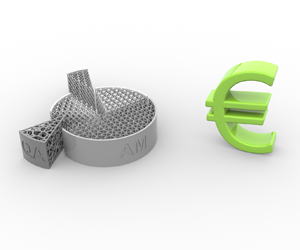

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.