Next Level Foundry Containers

Additive Manufacturing as the Future Repair Method in the Magnesium Die Casting Industry

A remarkable development is emerging in the world of manufacturing technology: the repair and reinforcement of the inner surface of casting containers for magnesium die casting using High Speed Laser Cladding (DED-LB/M).

This method offers an efficient solution for a common problem – wear.. Over time, this wear leads to efficiency losses and quality reductions in the casting process, often exceeding the limits of traditional methods.

In the InMaGie project, funded by the Federal Ministry for Economic Affairs and Climate Action, the Laser Cladding process is being tested to counteract the wear of casting containers.

Laser Cladding is an additive manufacturing process where metal material in the form of powder or wire is applied to a surface using a laser beam. This technique allows for precise and targeted application of material layers to repair and reinforce damaged or worn areas. Due to its precision and efficiency, Laser Cladding is ideal for complex geometries and high-quality repairs.

This involves applying a special material layer to the affected areas, not only extending the life of the casting containers but also improving the quality of the cast products.

This innovative method could be a cost-effective and efficient alternative to conventional repair or replacement procedures, contributing to more sustainable production: less material waste and longer service life of the casting containers lead to a significant reduction in ecological footprint.

InMaGie impressively demonstrates how innovative technologies can optimize existing processes and open new possibilities in industrial manufacturing.

This development is a clear example of how technological progress and sustainability can go hand in hand to meet the challenges of the modern manufacturing industry. An exciting look into the future of production technologies.

Image 1: High-Speed DED-LB/M of the inner surface of a demonstrator. © RWTH DAP.

Marie Bode, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Further News

DAP at RAPID+TCT

Take your Chance! The Potential of Strategic Production Planning for AM: Deep Dive with Stephan Ziegler at RAPID + TCT! Alongside ACAM, we are excited to be at RAPID + TCT this week, the premier fair for Additive Manufacturing and 3D printing. Our Chief Engineer,...

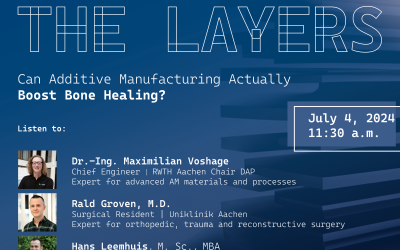

Sign Up, Grab Your Headphones and Tune into Our Audio Event

Attention, Innovators! Join Our Brand New Networking Format: Between the Layers Second Episode: Can Additive Manufacturing Actually Boost Bone Healing? JULY 4TH, 2024 | 11:30 A.M. (CET) | LINKEDINOUR GUESTS: RALD GROVEN | UNIKLINIK AACHEN & HANS LEEMHUIS |...

DAP at ADDITIVE 2024

Take your Chance! Next Level Alloy Development: Catch Marie-Noemi Bold at ADDITIVE 2024 in Bremen! She will dive into the fascinating world of High-speed Laser Directed Energy Deposition (HS DED-LB). Her presentation, titled "Influence of Process Parameters on...

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.