Next Level Alloy Development

Custom Alloys for Tool Manufacturing: The Potential of Additive Manufacturing

In an era where additive manufacturing is redefining industrial capabilities, customizing alloys for specific requirements is crucial.

As part of the IoP project (Internet of Production), Marie Bold (DAP) collaborated with colleagues at the Foundry Institute (GI) to merge CALPHAD simulations with HS DED-LB/M and create custom alloys for tool manufacturing.

The objective was to modify H11 steels, which are highly valued in the industry for their exceptional hardness and durability but are susceptible to cracking during additive processing. The modification of the alloy (known as H11m) decreased the proportion of retained austenite, which in turn reduced the need for subsequent heat treatments.

This modification is crucial because retained austenite has a negative impact on the mechanical properties of the alloys, and additional heat treatments are both expensive and time-consuming.

These achievements offer the potential for more efficient and cost-effective development and production of alloys for demanding applications, from aerospace to mechanical engineering. This reinforces additive manufacturing’s role as a key technology for future industrial applications.

The project is funded by the German Research Foundation (DFG).

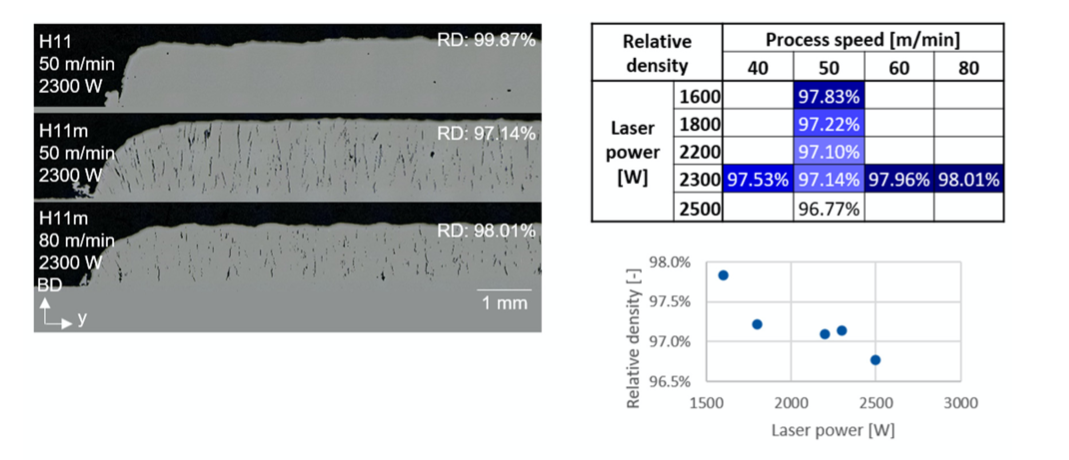

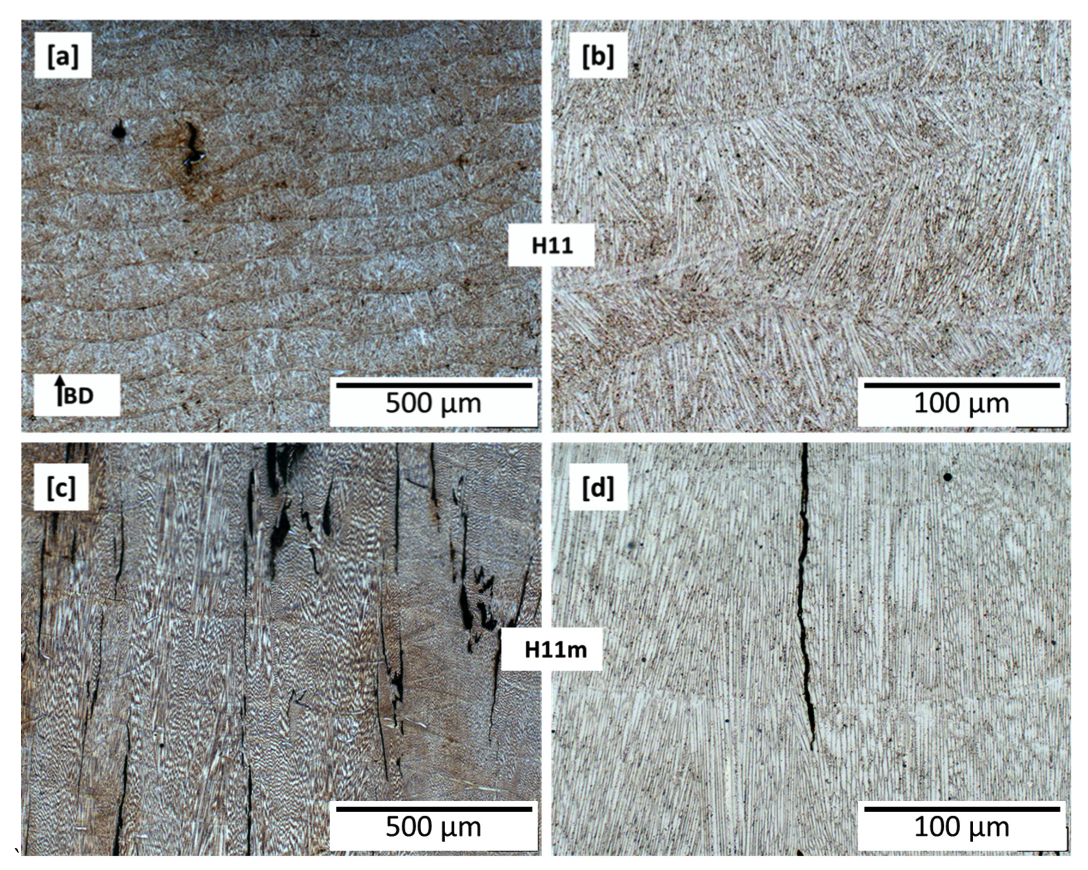

Image 1: Optical microscopy of samples manufactured

© RWTH DAP.

Image 1: LOM images of as-built 3DHSDED–LB/M samples

© RWTH DAP.

Jonas Boseila, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Further News

DAP at RAPID+TCT

Take your Chance! The Potential of Strategic Production Planning for AM: Deep Dive with Stephan Ziegler at RAPID + TCT! Alongside ACAM, we are excited to be at RAPID + TCT this week, the premier fair for Additive Manufacturing and 3D printing. Our Chief Engineer,...

Sign Up, Grab Your Headphones and Tune into Our Audio Event

Attention, Innovators! Join Our Brand New Networking Format: Between the Layers Second Episode: Can Additive Manufacturing Actually Boost Bone Healing? JULY 4TH, 2024 | 11:30 A.M. (CET) | LINKEDINOUR GUESTS: RALD GROVEN | UNIKLINIK AACHEN & HANS LEEMHUIS |...

DAP at ADDITIVE 2024

Take your Chance! Next Level Alloy Development: Catch Marie-Noemi Bold at ADDITIVE 2024 in Bremen! She will dive into the fascinating world of High-speed Laser Directed Energy Deposition (HS DED-LB). Her presentation, titled "Influence of Process Parameters on...

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.