Next Level Alloy Development

HS-DED: A Potential Game Changer for Efficient Alloy Development?

In the field of Additive Manufacturing (AM), the search for innovative solutions is ongoing.

When it comes to alloy design, traditional approaches are quite effective, but they may not be efficient when navigating the vast landscape of potential material compositions and process parameters.

A recent study led by DAP Expert Klaus Büßenschütt introduces the High-Speed Direct Energy Deposition (HS-DED) method as a promising approach to enhancing alloy design and production in AM.

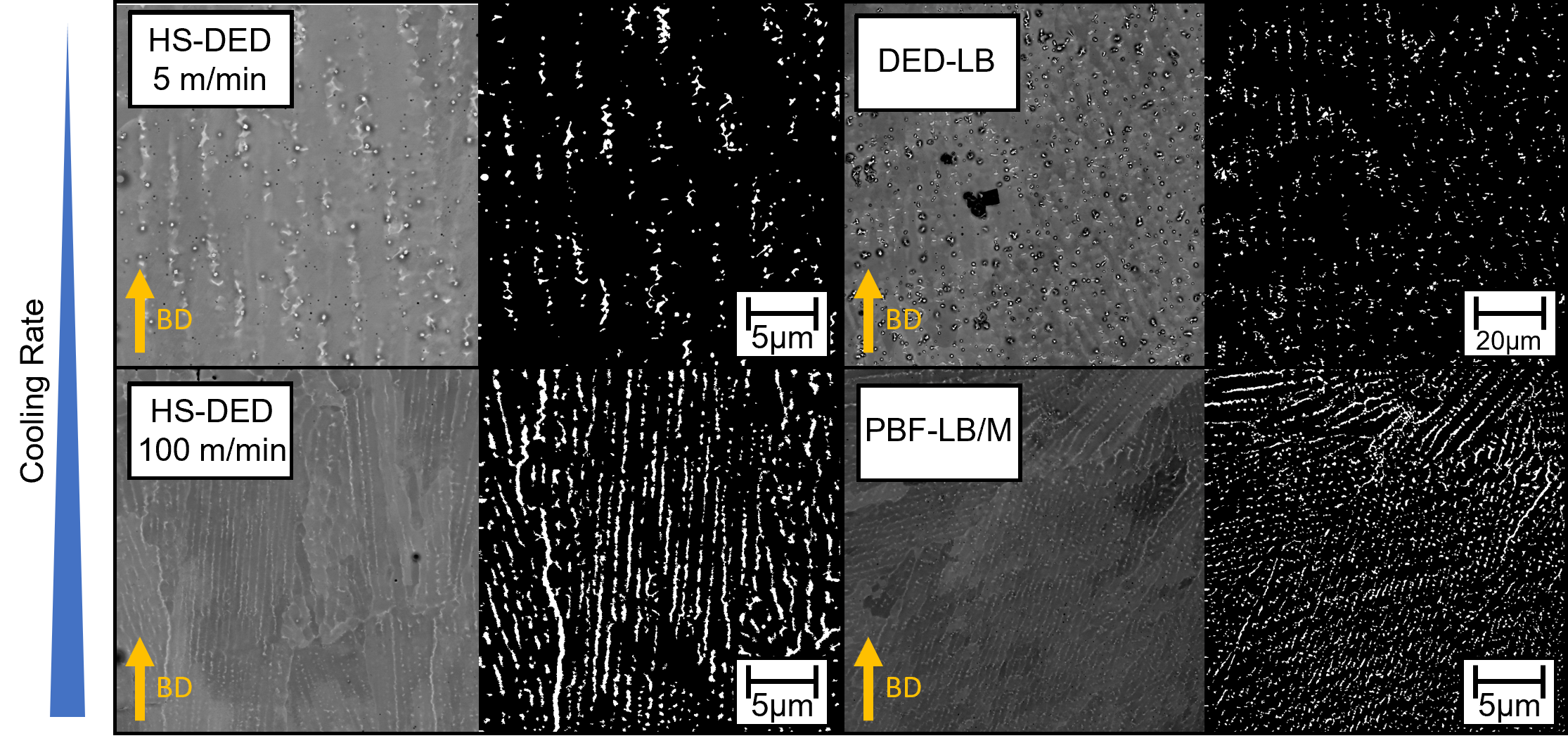

The study compares HS-DED to the currently dominant metal AM technologies, Laser Powder Bed Fusion (PBF LB/M) and conventional DED-LB, using nickel alloy IN718 as a reference.

By carefully examining resulting microstructures using optical and scanning electron microscopy, as well as energy-dispersive X-ray spectroscopy, this research evaluates the transferability of the HS-DED process.

The findings are promising, demonstrating that HS-DED can reproduce the range of cooling conditions and microstructural properties of PBF LB/M and DED-LB parts.

This breakthrough demonstrates the potential of HS-DED not only for rapid alloy development but also for enhancing the efficiency and sustainability of AM processes.

Moving forward, the implications of this study for the manufacturing industry and beyond are significant. By streamlining the alloy development process, HS-DED enables faster innovation cycles, reduced material waste, and the creation of more sustainable products.

This research is funded by the Digital Photonic Production DPP Research Campus and the NanoMatFutur project “MatAM – Design of additively manufactured high-performance alloys for automotive applications”by the he German Federal Ministry of Education and Research (BMBF) and by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation)

Klaus Büßenschütt, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Further News

DAP at RAPID+TCT

Take your Chance! The Potential of Strategic Production Planning for AM: Deep Dive with Stephan Ziegler at RAPID + TCT! Alongside ACAM, we are excited to be at RAPID + TCT this week, the premier fair for Additive Manufacturing and 3D printing. Our Chief Engineer,...

Sign Up, Grab Your Headphones and Tune into Our Audio Event

Attention, Innovators! Join Our Brand New Networking Format: Between the Layers Second Episode: Can Additive Manufacturing Actually Boost Bone Healing? JULY 4TH, 2024 | 11:30 A.M. (CET) | LINKEDINOUR GUESTS: RALD GROVEN | UNIKLINIK AACHEN & HANS LEEMHUIS |...

DAP at ADDITIVE 2024

Take your Chance! Next Level Alloy Development: Catch Marie-Noemi Bold at ADDITIVE 2024 in Bremen! She will dive into the fascinating world of High-speed Laser Directed Energy Deposition (HS DED-LB). Her presentation, titled "Influence of Process Parameters on...

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.