Press Release PEM RWTH Aachen, April 11th 2024

E-Motor Study: PEM and Partners Produce Stator Demonstrator

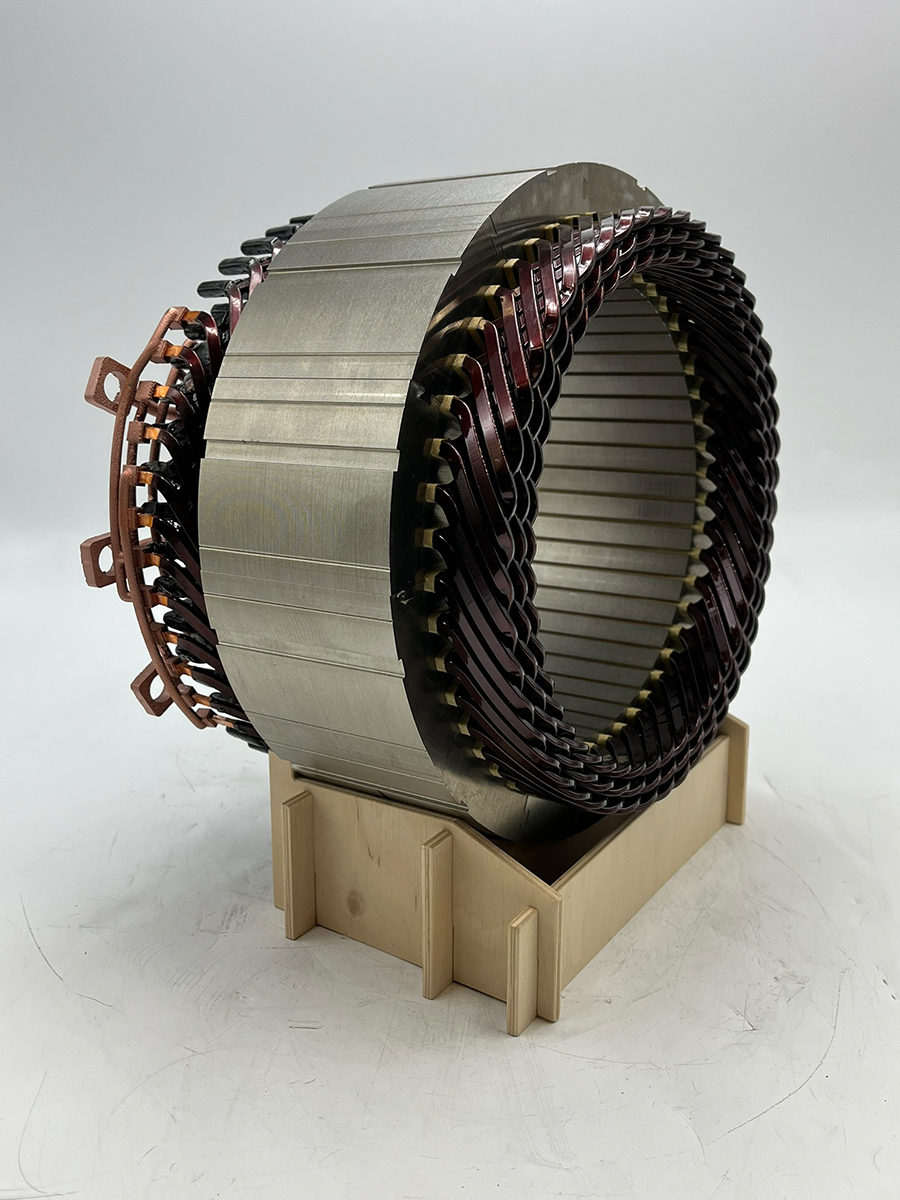

With numerous partners from industry, the Chair of Production Engineering of E-Mobility Components (PEM) of RWTH Aachen University has achieved the first goal of the “Innovative Materials in Electric Motors” consortium study. To this end, the participants produced a technology demonstrator for stators as the performance-determining component of electric motors, whose components contain innovative materials by using innovative production processes.

“The development and production of a holistic technology demonstrator can offer companies a platform for the targeted presentation of their own solutions,” says PEM Director Professor Achim Kampker. The consortium study is part of the Transformation Hub Scale-up E-Drive project funded by the Federal Ministry for Economic Affairs and Climate Action (BMWK), in which PEM is involved and which aims to support small and medium-sized companies in the technological transition to the production of electric vehicle drives through targeted measures. “Manufacturers with a high level of technological expertise in special applications for combustion engines must not lose touch with the ongoing change,” Kampker says.

Process documentation and preparation of the results

The consortium studyʼs stator demonstrators were produced on the basis of a neutral reference design and include process documentation and preparation of the results. At the end of March 2024, the project was presented to the public for the first time at a special booth at Coiltech, Europeʼs largest electric motor technology trade fair, in Augsburg, Germany. In October 2024, the project will be presented at the renowned Electric Vehicle Production Days (EPT) organized by PEM. In the future, the consortium could also produce a technology demonstrator for rotors.

Overview with specific information

In addition to PEM and dap of RWTH Aachen University, the consortium includes the companies 3M GmbH, AMS Anlagenbau GmbH & Co. KG, C.D. Wälzholz GmbH & Co. KG, GH-Induction Deutschland GmbH, LCD LaserCut AG, Röscher GmbH, Schaeffler ELMOTEC STATOMAT GmbH, Schwering & Hasse Elektrodraht GmbH, SWD AG, TRUMPF Laser- und Systemtechnik GmbH, WAFIOS AG and Wickeder Westfalenstahl GmbH. Comprehensive explanations of the planned processes and products can be found in the Manufacturing a Stator Primotype Using Innovative Materials and Processes summary.

Source: PEM RWTH Aachen

Image 1: Demonstrator for an innovative e-motor strator. © PEM RWTH Aachen University | Till Backes

Carsten Putz, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Group Leader

Campus-Boulevard 73

52074 Aachen

Further News

ProCloud3D: Developing a Cloud-Based Platform for Secure Decentralized Additive Manufacturing

Press Release, March 20th 2024 ProCloud3D: Developing a Cloud-Based Platform for Secure Decentralized Additive ManufacturingIn a German-Chinese project consortium, the Chair Digital Additive Production DAP at RWTH Aachen University has developed the architecture for a...

The Implant of the Future: Production of Resorbable patient-specific Implants using LPBF

Press release, MArch 7th 2023 The Implant of the Future: Production of Resorbable patient-specific Implants using LPBF As part of the BioStruct project, the Aachen-based medical technology innovation ecosystem is researching the further development of patient-specific...

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.