Next Level Alloy Development

Powder to the People: BlendAM’s Vision for Streamlining Alloy Development

Imagine a future where creating complex and high-strength alloys starts with a simple mixing of powders.

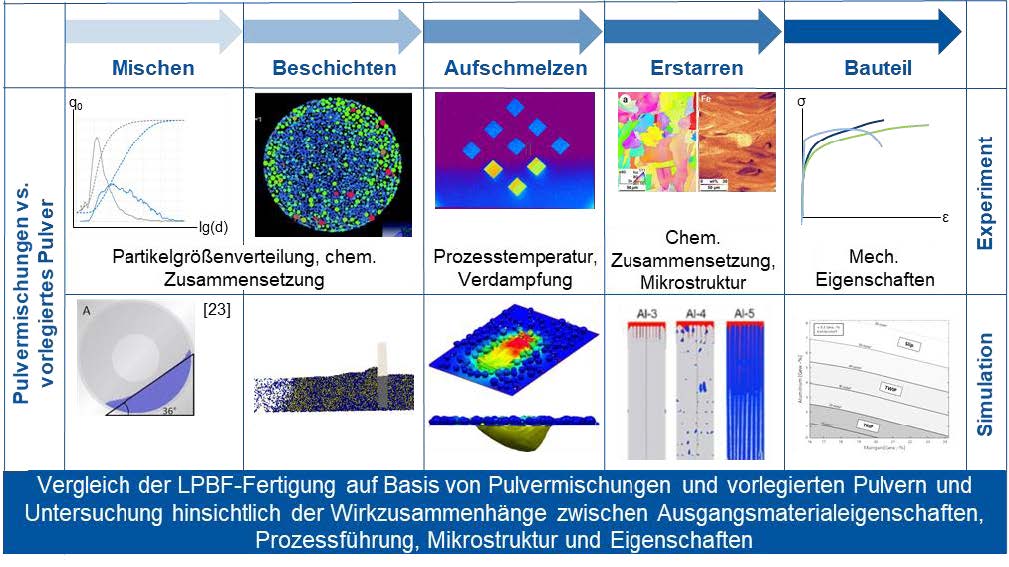

That future is being crafted today, thanks to the BlendAM project. This cutting-edge research is exploring the uncharted waters of powder mixtures in Laser-Based Powder Bed Fusion of Metals (PBF-LB/M)

The main goal of BlendAM is to investigate the possibility of creating bespoke alloys by pre-mixing different metal powders and using them directly in PBF-LB/M printing.

Why does this matter?

The common process of creating metal alloy powders is time and cost demanding.

To create a usable homogeneous alloy for printing in PBF-LB/M, it is necessary to first melt different metals together and then atomize them into a fine powder.

The ability to print with pre-mixed metal powders without compromising material quality or structural properties would therefore make the development of new alloys more agile, by eliminating the need for separate powder atomisation each time.

BlendAM’s research could influence how materials are developed for additive manufacturing technologies, offering unprecedented flexibility and innovation.

So, what does this mean for industries across the globe? A new era of manufacturing possibilities, where the only limit is imagination?

Stay tuned as we continue to mix, melt, and mold the future of Additive Manufacturing!

Funding: DFG – Deutsche Forschungsgemeinschaft e.V.

Consortium:

‘Materials für Additive Manufacturing’, TU Berlin

Jonas Boseila, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Further News

DAP at RAPID+TCT

Take your Chance! The Potential of Strategic Production Planning for AM: Deep Dive with Stephan Ziegler at RAPID + TCT! Alongside ACAM, we are excited to be at RAPID + TCT this week, the premier fair for Additive Manufacturing and 3D printing. Our Chief Engineer,...

Sign Up, Grab Your Headphones and Tune into Our Audio Event

Attention, Innovators! Join Our Brand New Networking Format: Between the Layers Second Episode: Can Additive Manufacturing Actually Boost Bone Healing? JULY 4TH, 2024 | 11:30 A.M. (CET) | LINKEDINOUR GUESTS: RALD GROVEN | UNIKLINIK AACHEN & HANS LEEMHUIS |...

DAP at ADDITIVE 2024

Take your Chance! Next Level Alloy Development: Catch Marie-Noemi Bold at ADDITIVE 2024 in Bremen! She will dive into the fascinating world of High-speed Laser Directed Energy Deposition (HS DED-LB). Her presentation, titled "Influence of Process Parameters on...

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.