The Faces behind Our Research

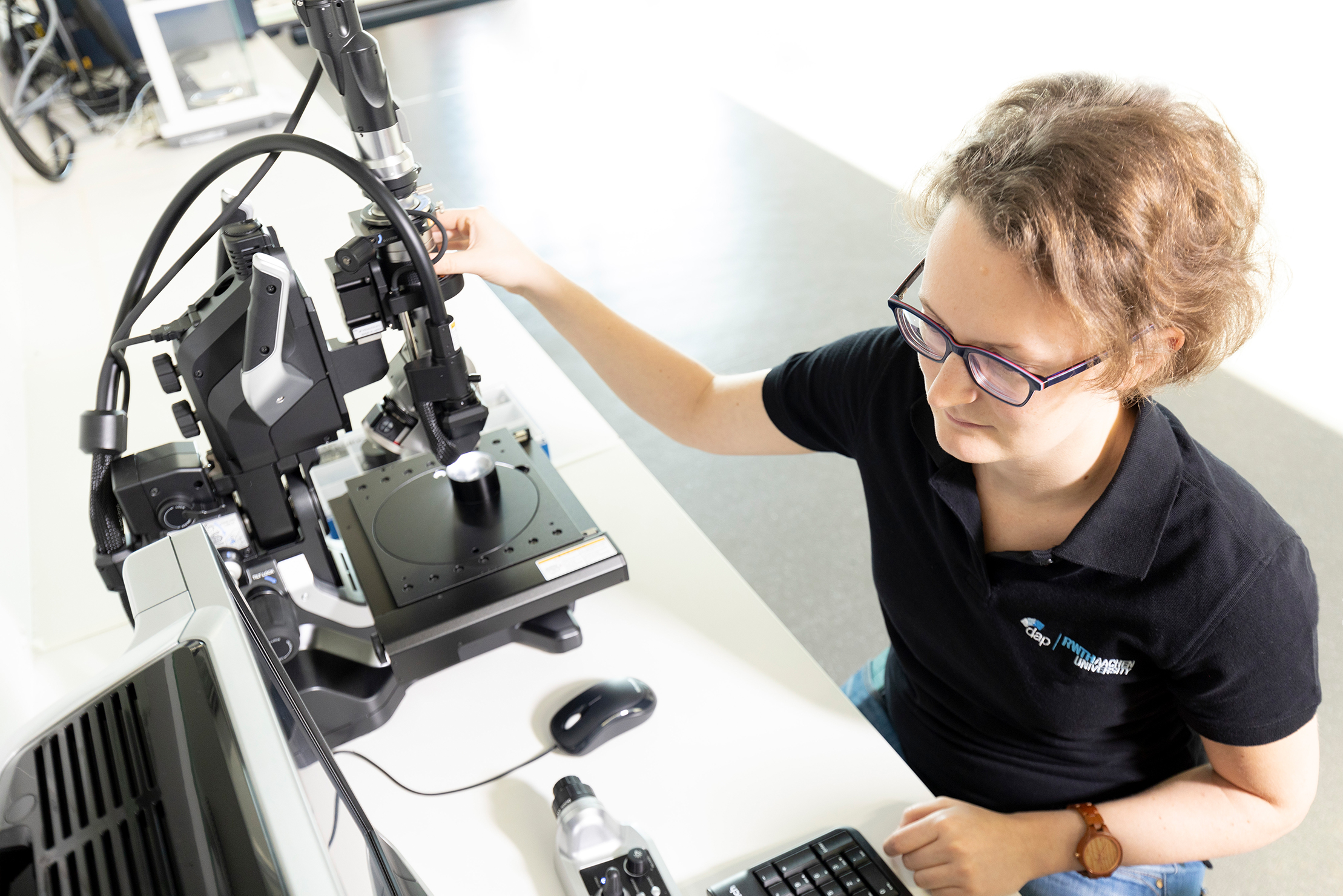

#IamDAP: Marie Bold

Marie has been a scientific associate at our chair since 2018. She focuses her work especially in the thematic area of (Extreme High-Speed) Laser Material Deposition and materials development for Additive Manufacturing (AM). In her dissertation she deals with the question: “How are alloy composition, microstructure and hardness affected in the EHLA process?”. Since 2021 she has now also taken over the group lead of the Advanced Materials group.

Marie, you studied materials science at the RWTH Aachen University. Have you already been interested in STEM topics during your school years?

Actually, yes! Being a little nerd, natural sciences have always interested me very much. Sometimes to my family’s costs, when, once again, I conducted self-designed experiments. Nevertheless, I was also excited about learning new languages – a great thing about school for me: I had the possibility to learn so many different things at the same time!

Today, materials science also accompanies you in your work at our chair. Why did you decide to contribute your materials knowledge in the field of Additive Manufacturing?

In the middle of my bachelor studies, I already knew that I would focus on metallic materials. My first contact with Additive Manufacturing was through friends from mechanical engineering towards the end of my studies. I quickly realized that, for example, extreme process conditions can lead to extraordinary effects in the materials. In combination with the fact that mainly mechanical engineers were active in Additive Manufacturing, it was clear to me that I could make a good contribution there!

So, how can you use your knowledge from your studies in your work at our chair?

In my studies, I learned a lot about the metal-physical mechanisms that determine the properties of the material, for example. I know how to promote or suppress these mechanisms through targeted process or temperature control in order to achieve a specific property profile. In addition, it is indeed very helpful that I have a comprehensive knowledge of common analytical methods for microstructure and property determination, for example, to find out: Which method is at all suitable to investigate the microstructure? For my materials investigations of samples manufactured using Extreme High-Speed Laser Material Deposition (EHLA), to give an example, I quickly reach the optical microscope’s limits and have to switch to a more complex scanning electron microscope.

Buzzword EHLA: You are investigating this Additive Manufacturing process in order to qualify it as a possible tool to develop powder-based alloys especially adapted to AM processes. What is the motivation behind this?

For materials development, in this case powder-based alloy development, it is necessary to be able to selectively vary the chemical composition and the solidification conditions of the material, because this primarily influences its properties. With the EHLA process, we can adjust the chemical composition of the powder material within seconds through local powder feeding, so that a wide variety of materials can be processed quickly for subsequent screening. In addition, the solidification conditions can be varied by process parameters, such as the process speed. Therefore, EHLA fulfills the essential requirements for fast and resource-efficient material development.

…and talking about motivation: What vision do you associate with the development of new materials for Additive Manufacturing?

My vision is to finally exploit the full potential of Additive Manufacturing via customized and improved materials and, hence, to make products even more efficient. For me, this means, for example, improving the sustainability and resource efficiency of additively manufactured components through lightweight applications or longer product lifetimes.

Finally, a question that is also not far away from the topic of motivation: Your answer to the question “Either elevator or stairs” is stairs – sounds sporty?

Yes, at least I endeavor to be…even if I do take the elevator in the morning when I’ve already climbed 80 meters on my bike. But it’s basically true: I prefer to use my own physical strength to get around, regardless of whether I’m participating the Campus or Lousberg Run in Aachen, riding my bike in everyday life, or taking long-distance bike tours on vacation.

Marie Bold, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Further News

All good things go by three: Kick-off of the HyInnoNets Project

Project-Kick-Off All Good Things Go by Three: Kick-off of the HyInnoNets Project, Part of the Zukunftscluster Wasserstoff Recently, the consortium of the HyInnoNets project has met at the ITA Institut für Textiltechnik of the RWTH Aachen University. The project...

And another one: Kick-off of the HyInnoBurn Project

Project-Kick-Off ...and another one: Kick-off of the HyInnoBurn Project, also Part of the Zukunftscluster Wasserstoff The HyInnoBurn project deals with the development of optimized industrial gas burners for flexible operation with natural gas and hydrogen. Since the...

Getting on track: Kick-off of the HyInnoCells Project

Project Kick-Off Getting on Track: Kick-off of the HyInnoCells project As part of the Zukunftscluster Wasserstoff the project researches the flexible production of electrochemical cells. In particular, the focus is on electrolysers for water electrolysis - currently...

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.