the faces behind our research

#IamDAP: Moritz Kolter

Moritz has been a part of the DAP chair since February 2021. Before joining the chair, he studied mechanical engineering at TU Munich. Thematically, he examines the potential of streaming in the context of 3D printing. This is also the topic of his dissertation, in which he investigates the effects of streaming on business models in 3D printing. In May 2022 Moritz became the new head of the Digital Production group.

→ Moritz’ Profile at a glance

Moritz, you technically studied mechanical engineering. How come you are not building machines today, but instead are working with digital processes in Additive Manufacturing?

Only constructing machines is simply not enough these days. The majority of innovation comes from digitization and software. These are also the points that set you apart from others. I noticed early on in my studies, that you can get cool products up and running pretty quickly through intelligent programming. That excited me right away. And that is also why I chose relatively few classical elements of mechanical engineering and many IT topics for my studies, which then continued in my internships and also in my further choices of career.

You are working on utilizing the potential of streaming for 3D printing. Many people know about streaming through on-demand video platforms. How do you imagine a stream for 3D printing?

3D printing is a process in which components are created layer by layer. We stream the information about how these individual layers are to be printed from the cloud directly to the printer. With Netflix, for example, individual images are streamed, which then together result in a video. In 3D printing, images are the individual layers, and the result is not a video, but a component.

What would be the benefits of a “Netflix” for 3D printing?

The benefits are broadly comparable to those of an on-demand video platform. We also use streaming in 3D printing to send the data exactly where it is needed. If, for example, a customer of a German company is based in China, then the component nowadays often still must be manufactured in Germany first to be shipped after. Our approach is to use streaming to send the assembly instructions directly to a printer in China. This saves us a lot of logistics, which in the end always means time and money.

What can you tell us about the current state of research?

We are currently implementing a streaming protocol with which we can stream the data. To do this, we are using the so-called Open Vector Format, which, compared to other formats in 3D printing, allows us to send the data layer by layer. In addition, we are working on the security of the streaming to avoid piracy and the like. The latter is also the motivation behind streaming because the advantages described earlier could also be achieved simply by sending the print data digitally, but then you lack control and data security.

The Open Vector Format was co-developed by scientists of the DAP chair. Why is this format so important for additive manufacturing?

As mentioned earlier, additive manufacturing is a layer-by-layer process and therefore we not only have classic 3D data, but also so-called 2.5D data, in other words: the layers. Until now, every manufacturer has been doing their own thing: data is described and stored differently. However, this is a problem both for research and for productive operation in the industry. It often complicates the process, which leads to the development of isolated solutions. At this point, we hope that the Open Vector Format will change that, as it is open-source and optionally extensible. In fact, the whole thing is just gathering pace, because many partners in the industry are slowly understanding the added value and are helping to expedite the topic.

What about outside of work, is Netflix also very popular with you in your private life?

On rainy or lazy Sundays or even when there’s an exciting new series that I like to binge-watch. Otherwise, I like spending time in the outside world, going mountain biking in the Aachen Forest, or bouldering with friends. That also provides a good balance to the digital workday.

Moritz Kolter, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Furhter news

DAP at RAPID+TCT

Take your Chance! The Potential of Strategic Production Planning for AM: Deep Dive with Stephan Ziegler at RAPID + TCT! Alongside ACAM, we are excited to be at RAPID + TCT this week, the premier fair for Additive Manufacturing and 3D printing. Our Chief Engineer,...

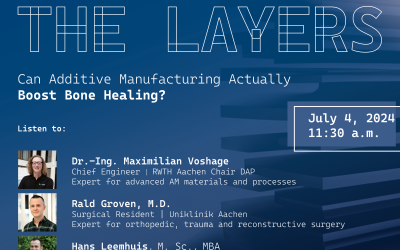

Sign Up, Grab Your Headphones and Tune into Our Audio Event

Attention, Innovators! Join Our Brand New Networking Format: Between the Layers Second Episode: Can Additive Manufacturing Actually Boost Bone Healing? JULY 4TH, 2024 | 11:30 A.M. (CET) | LINKEDINOUR GUESTS: RALD GROVEN | UNIKLINIK AACHEN & HANS LEEMHUIS |...

DAP at ADDITIVE 2024

Take your Chance! Next Level Alloy Development: Catch Marie-Noemi Bold at ADDITIVE 2024 in Bremen! She will dive into the fascinating world of High-speed Laser Directed Energy Deposition (HS DED-LB). Her presentation, titled "Influence of Process Parameters on...

DAP at SurfaceTechnology

Take your Chance! A new opportunity for multi-material coatings: discover Separate Powder Injected DED-LB at SurfaceTechnology This week, the SurfaceTechnology GERMANY opens its doors in Stuttgart! This international event brings together leading experts to present...

Week of Environment

04.05. - 05.05.2024, Berlin, germany The DAP at Week of Environment Soon, the "Week of the Environment" will open its doors! Organized by the German Federal Environmental Foundation (DBU), this event brings together leading experts and enthusiasts to showcase...

DAP x EOS: Metal Symposium in Aachen

Take your Chance! "Unleash Your Power" at the Metal Symposium in Aachen We need to think beyond previous manufacturing limitations: The world of additive manufacturing is changing. Applications that once seemed impossible are now a reality. To dive deeper into the...

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.