The Faces beyond Our Research

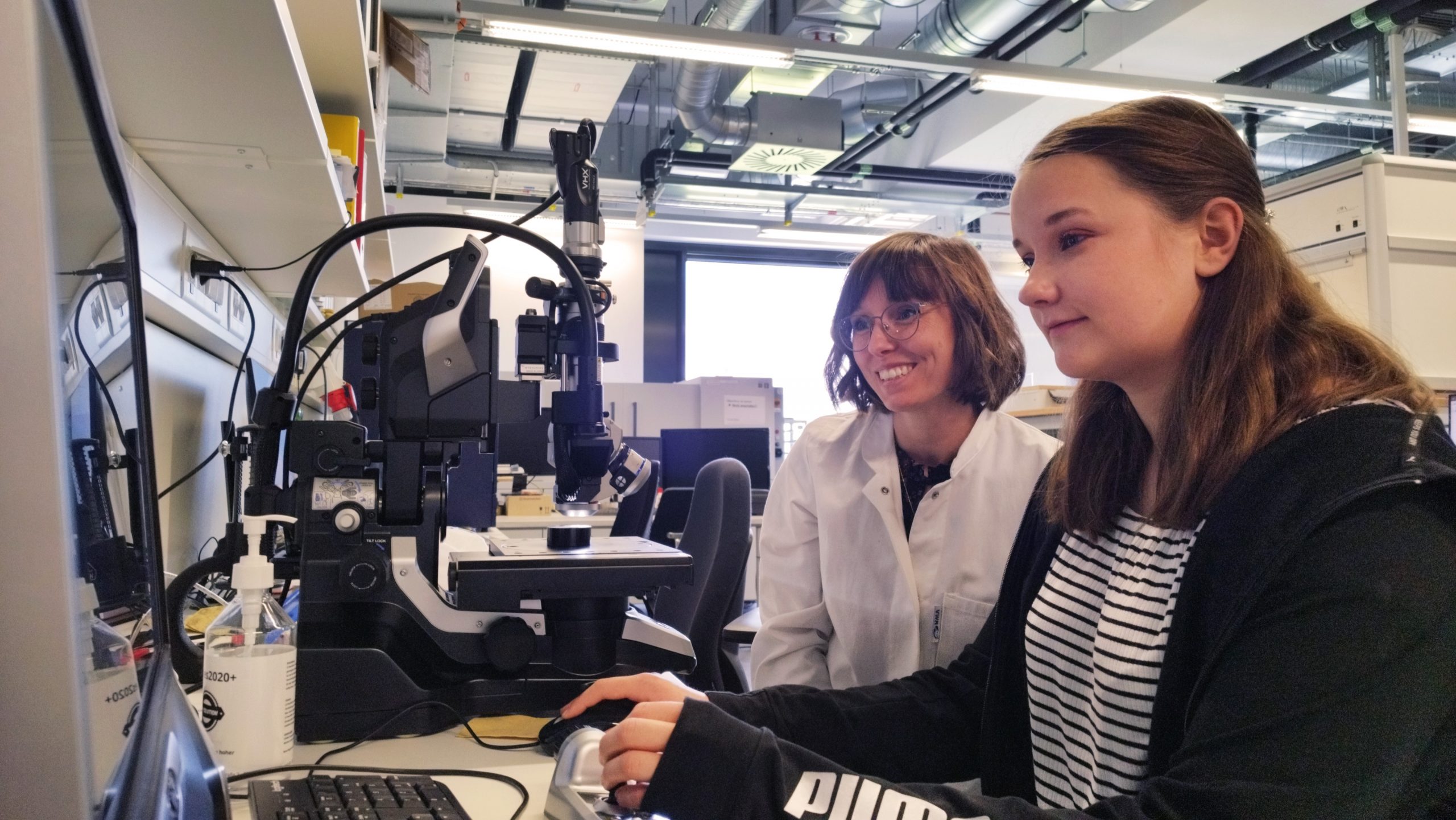

#IamDAP: Sabine Fröhlich

Sabine joined the DAP in 2020 to help building our metallographic and analytical laboratory. Leading the Metallography department, Sabine coordinates the functioning of the laboratory as well as the training of material testers and support staff.

Sabine, you originally trained as a physics laboratory assistant. Today, you work in metallography and material analysis, studying the properties of different materials. Did you already know during your training that you wanted to work in this field?

No, it wasn’t clear to me at the time. However, exploring the “why” has always been important to me. That’s the reason I wanted to get into research and development. As someone from Aachen, the RWTH was the obvious choice. Fortunately, in 1998, I had the opportunity to start my training at the RWTH, specifically at the Chair of Semiconductor Technology (IHT), as a physics laboratory assistant. I remained loyal to the RWTH and later switched institutes to broaden my perspective.

I transitioned from semiconductor technology, with a few smaller stops along the way, to the Chair of Ceramic Components in Mechanical Engineering (IKKM). It later merged with IWK to form IWM under the leadership of Professor Beiss. Eventually, Professor Broeckmann took over IWM. During my time there, I worked as the head of the thermophysical laboratory, which initially had a small team. Consequently, I aided in ceramicography and scanning electron microscopy, gaining a broad knowledge base and a comprehensive understanding of various laboratory areas and their processes. As time went on, my role evolved, and I was able to focus on my passion for instrumental analytics in thermal analysis. After 13 years, seeking new experiences, I moved to the GHI (Glass Chair) where I specialized in studying glasses and their thermokinetics.

What led you to join our chair? Were you familiar with additive manufacturing before coming here?

After over 21 years, I had gained considerable experience and developed a strong network at the RWTH. In early 2020, I heard that the DAP was seeking support in establishing its own metallographic and analytical laboratory. I had thoroughly enjoyed setting up thermal analysis at IKKM/IWM, and this opportunity allowed me to be part of a young chair with an incredibly exciting, completely new topic. It was a chance to contribute to building a suitable laboratory once again. Having worked with ceramics, (hard) metals, and glass using traditional manufacturing processes, I was eager to dive deeper into additive manufacturing and explore the diverse possibilities of component fabrication and material compositions. I couldn’t pass up this opportunity.

At the DAP, you are part of the Advanced Materials group and lead the metallography department. Can you give us some insight into your work?

My work ranges from incredibly exciting tasks to those that are also important but less thrilling. Ensuring the smooth functioning of the laboratory for my colleagues takes up a significant portion of my time. This includes maintaining a focus on work safety, coordinating the training of material testers and support staff, and managing internal and external investigation orders.

Choosing the best analytical methods and implementing them to solve specific problems or tasks can be challenging. Therefore, I enjoy providing guidance to my colleagues, whether it’s advising on these issues or helping with project planning. In my spare time, when I’m not needed elsewhere, I prefer to dive deeper into new methods and expand my expertise.

In the context of metallography, you have a unique perspective on additive manufacturing, observing it through the microscope. What are the critical details that suitable materials for AM must possess?

There is no one-size-fits-all answer to this question. The DAP is known for its diverse range of projects. Each project focuses on different applications, manufacturing processes, materials, and research objectives. Consequently, the material requirements vary significantly based on the corresponding projects. However, this is what makes working at the DAP so fascinating. It’s a continuous learning process where I often feel like a detective, seeking the solutions and understanding the factors at play. Over time, our equipment park has expanded, providing us with more than just a “magnifying glass” to conduct our research.

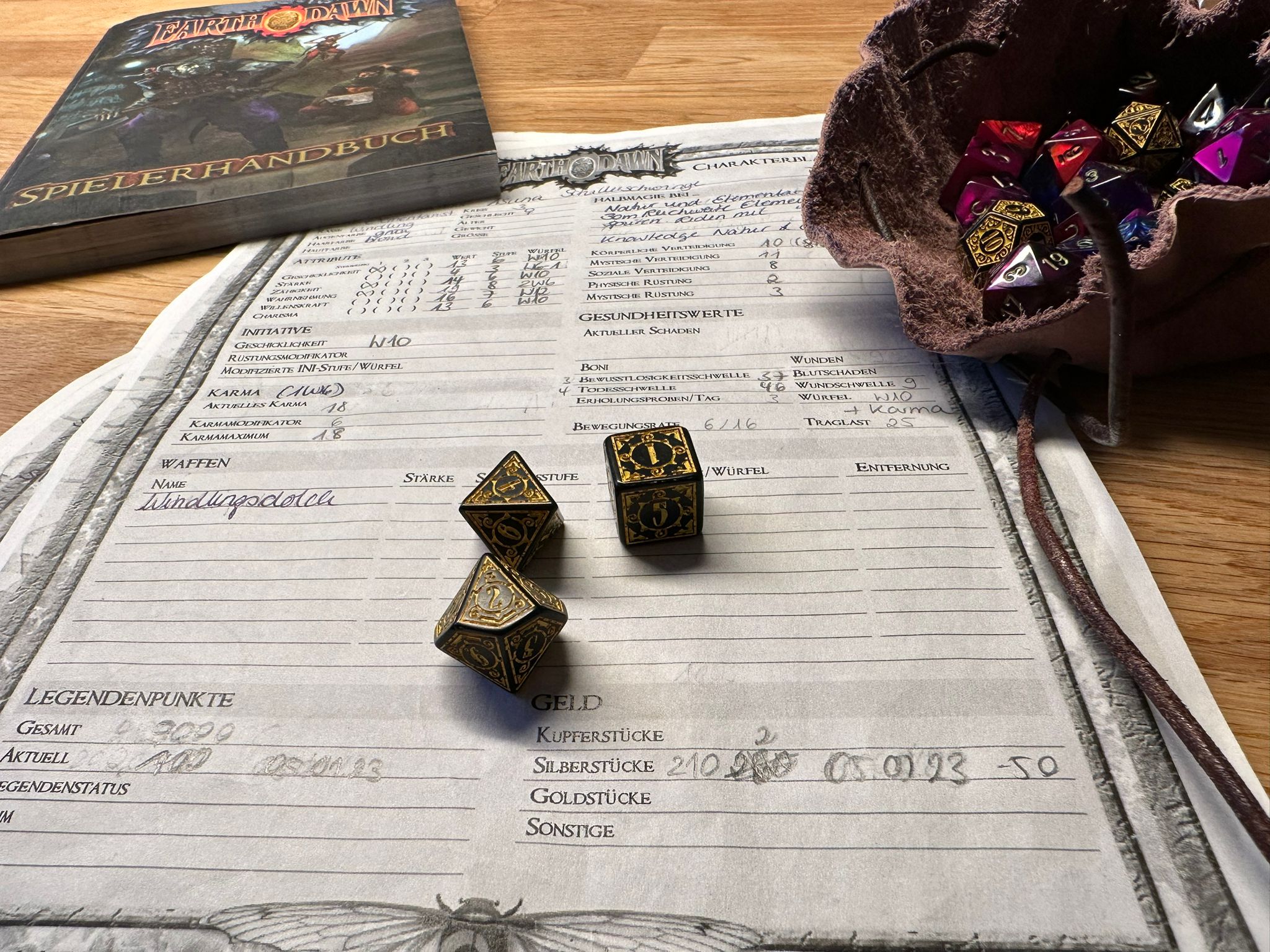

Do the small things in life also hold significance for you outside of work?

Absolutely! Outside of work, I value variety, mental relaxation, and creativity. Spending time with my family, whether it’s going on bike rides, engaging in board games or crafts, or working on building projects together, is just as important to me as having regular social evenings with friends. We enjoy activities such as pen-and-paper role-playing games, MMORPG gaming, or board game sessions. Additionally, I make sure to dedicate time for myself to unwind, whether it’s through reading a good book in a relaxed atmosphere, gardening, or exploring new creative projects.

Sabine Fröhlich

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Further News

DAP at RAPID+TCT

Take your Chance! The Potential of Strategic Production Planning for AM: Deep Dive with Stephan Ziegler at RAPID + TCT! Alongside ACAM, we are excited to be at RAPID + TCT this week, the premier fair for Additive Manufacturing and 3D printing. Our Chief Engineer,...

Sign Up, Grab Your Headphones and Tune into Our Audio Event

Attention, Innovators! Join Our Brand New Networking Format: Between the Layers Second Episode: Can Additive Manufacturing Actually Boost Bone Healing? JULY 4TH, 2024 | 11:30 A.M. (CET) | LINKEDINOUR GUESTS: RALD GROVEN | UNIKLINIK AACHEN & HANS LEEMHUIS |...

DAP at ADDITIVE 2024

Take your Chance! Next Level Alloy Development: Catch Marie-Noemi Bold at ADDITIVE 2024 in Bremen! She will dive into the fascinating world of High-speed Laser Directed Energy Deposition (HS DED-LB). Her presentation, titled "Influence of Process Parameters on...

DAP at SurfaceTechnology

Take your Chance! A new opportunity for multi-material coatings: discover Separate Powder Injected DED-LB at SurfaceTechnology This week, the SurfaceTechnology GERMANY opens its doors in Stuttgart! This international event brings together leading experts to present...

Week of Environment

04.05. - 05.05.2024, Berlin, germany The DAP at Week of Environment Soon, the "Week of the Environment" will open its doors! Organized by the German Federal Environmental Foundation (DBU), this event brings together leading experts and enthusiasts to showcase...

DAP x EOS: Metal Symposium in Aachen

Take your Chance! "Unleash Your Power" at the Metal Symposium in Aachen We need to think beyond previous manufacturing limitations: The world of additive manufacturing is changing. Applications that once seemed impossible are now a reality. To dive deeper into the...

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.