the faces behind our research

#IamDAP: Henrik Kruse

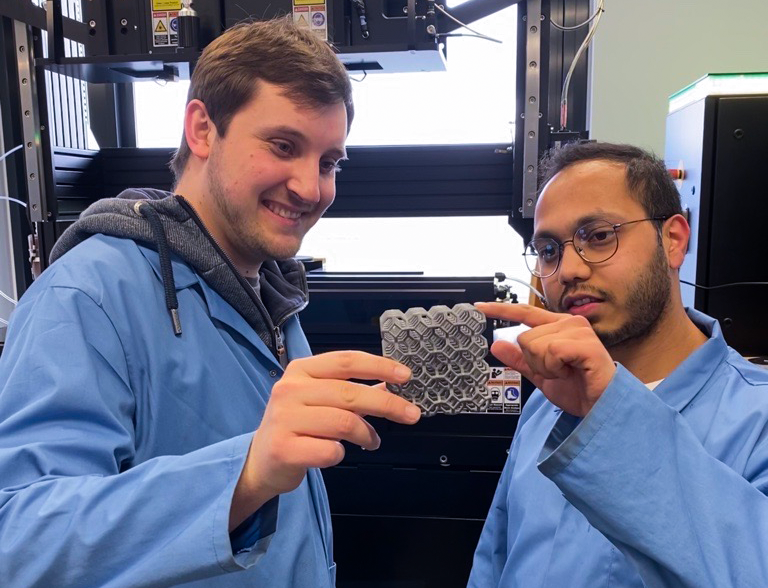

Henrik is a materials scientist who joined the Digital Product group in March 2021. He has had a passion for metallic materials since his undergraduate studies at RWTH Aachen. He first encountered Additive Manufacturing while working as a student assistant at the Fraunhofer ILT. In his research, Henrik concentrates on improving support structure generation in Additive Manufacturing and optimizing grid structures.

MHenrik, you bring a valuable skillset to DAP as a true materials scientist. Good for us, because when it comes to material, we are talking about a cornerstone of Additive Manufacturing. Did you have a clear goal in mind to work in this field while studying?

Since the start of my bachelor’s degree, I have been passionate about metallic materials, and I knew that materials science would play a crucial role in future technological advancements. I initially considered a career in surface technology and nanostructuring, which have always fascinated me since childhood due to their use of interesting physical effects such as the lotus effect.

At DAP, you are part of the Digital Product group and, among other things, responsible for project management. How did you actually end up with us?

My interest in Additive Manufacturing was sparked by my friends and my work as a student assistant at the Fraunhofer ILT. I wrote my Master’s thesis at DAP on the topic “Comparison of the solidification behavior of IN718 in Additive Manufacturing processes” and found that this was a very exciting research environment where I could contribute.

Project management is obviously not your research area. Can you give us an insight into your research?

Yes, of course. My research centers on improving support structure generation and optimizing grid structures, which are also referred to as digital materials. I aim to reduce material, time, and cost in the Additive Manufacturing process chain, thereby increasing resource efficiency. I conduct experimental studies of grid structures to explore their industrial potential for novel or improved applications.

Why are support structures important in Additive Manufacturing?

Support structures in Additive Manufacturing are crucial to ensuring component integrity during the manufacturing process. Additive Manufacturing is done layer by layer, and parts of the component that are not supported by support structures may collapse or deform. Thus, it’s essential that the support structures provide adequate support to the component to ensure that it has the desired shape and size. Support structures can also reduce the need for post-processing and make it easier to remove components from the printer. In short, support structures have a direct impact on costs, duration, quality, and functionality in the Additive Manufacturing process chain.

A philosophical question: what supports the support structures?

That’s a thought-provoking question. One could say that the support structures are supported by the fundamental laws of physics and the nature of matter, or that they are part of a larger structure that is supported by other parts. Practically speaking, the support structures are supported by the substrate plate or build platform, which is in turn supported by the machine.

You not only master the entire range of materials sciences, but also the entire range of the piano. Where do you need more finesse?

Playing the piano involves hitting the right notes, harmonies, and volumes. During work hours, it requires coordination to manage students, projects, and tasks, and create an efficient and successful work environment. Both require a certain level of precision, but at different degrees. Although I have a good touch in both areas, I spend significantly more time working, and that is where I place my focus.

Henrik Kruse, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Further news

It’s beginning to look a lot like Christnest!

The Nesting Optimizer in Christmas Spirit It's beginning to look a lot like Christnest! Actually, our nesting optimizer efficiently packs components into the build space of a PBF-LB system, but take a look: It has caught the Christmas bug too. Imagine our nesting...

Federal Voluteer Service at DAP: Interview with Annika Jongen

interview Annika's Journey with the DAP during her Federal Volunteer Service Meet Annika Jongen, who embarked on a journey with us as part of her Federal Volunteer Service. Over the span of four months, she was part of our team, gaining unique insights into our...

DAP Best Practice Magazine Vol. 2: Inventing the Future of Medical Technology

DAP Best-Practice Magazine, vol.2 Inventing the Future of Medical Technology How the DAP Chair and Meotec are inventing the future of medical technology, developing patient-specific resorbable implants with innovative designs and new material compositions....

Small Print matters: New 3D Printers for Gymnasium der Stadt Alsdorf

joint action Small Print matters: New 3D Printers for Gymnasium der Stadt Alsdorf Learning is like 3Dprinting - It starts at the basic level, takes time and sometimes needs adjustments to reach a goal. And the earlier you start, the faster you get where you want to...

All good things go by three: Kick-off of the HyInnoNets Project

Project-Kick-Off All Good Things Go by Three: Kick-off of the HyInnoNets Project, Part of the Zukunftscluster Wasserstoff Recently, the consortium of the HyInnoNets project has met at the ITA Institut für Textiltechnik of the RWTH Aachen University. The project...

And another one: Kick-off of the HyInnoBurn Project

Project-Kick-Off ...and another one: Kick-off of the HyInnoBurn Project, also Part of the Zukunftscluster Wasserstoff The HyInnoBurn project deals with the development of optimized industrial gas burners for flexible operation with natural gas and hydrogen. Since the...

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.