the faces behind our research

#IamDAP: Jonas Zielinski

Jonas is (almost) a Ph.D. physicist and founding member of the DAP chair. As part of the Digital Product group, he is thematically involved in the modeling of the relevant physical sub-processes along the Additive Manufacturing process chain.

→ Jonas’ Profile at a glance

Jonas, you studied physics. One might think of complex formulas and theories, but not primarily of additive manufacturing. How is it that you are now working precisely in this field?

I decided to study physics and specialize in elementary particle physics because I wanted to understand what holds the universe together at its core. This knowledge became partially available to me in the master’s program at RWTH Aachen University. However, when choosing my master’s thesis, I decided to solve a real – and not too abstract – problem for once. That’s how I encountered the “Integration of the free boundary value problem in laser build-up welding” at the Fraunhofer ILT and learned how to model physical subprocesses, formulate them in a numerically solvable way and simulate them, to obtain quite good approximate solutions. Suddenly, the world was not only mathematically describable but also solvable to a certain extent!

So, you work (mostly) with simulation. What exactly do you simulate at the DAP Chair?

I simulate almost all aspects or sub-steps that occur in Additive Manufacturing. Besides the “classical” melt pool simulation for a rough parameter pre-selection or the determination of the solidification conditions, the microstructure, or the component distortion, I also try to improve the design of products for Additive Manufacturing and the subsequent application together with my colleagues.

Do you also develop software to improve digital processes?

In fact, I develop software to improve physical processes, such as the manufacturing of a component or the process strategy, for example, to prevent local overheating in the LPBF.

Can Additive Manufacturing even exist without simulation?

Of course, if you want to improve components iteratively and manually until they can actually be manufactured without defects, you can leave the simulation aside. However, if you want to manufacture high-performance products cost-efficiently, you need a reasonable, robust digital process chain including component simulations!

An important question for you as an expert: What is the probability that we live in a simulation?

13% – although I can of course understand the attraction of more highly developed civilizations to create intelligence; a presumably very computationally intensive process. But to create physical quantum laws and to reproduce everything to the smallest and largest? An enormous expenditure… In addition, there is the problem of the recursive simulation – what happens if the simulated civilization (thus in your question we) also begins with the simulation of intelligence or even cosms?! (And the probability would be already high since one would simulate not only a universe but would certainly start a sensitivity analysis – I at least). Therefore, a chance of under 50%, the exact value of 13% comes about because specific answers sound more credible. 😀

When you’re not walking along the digital process chain, you’re also regularly seen climbing walls or rock faces. Do you let a computer calculate the perfect ascent beforehand, or is the journey the reward?

The journey is always the goal. The modeling of the processes or the software-technical implementations occupy me in my working time much longer than the evaluation of the “colorful pictures” which are usually only perceived as a simulation. Before a climb, you naturally develop a strategy for how you want to approach a particular route – but usually the initial assessment is not quite correct, so that you always have to readjust while keeping a cool head at dizzying heights.

Jonas Zielinski, M. Sc.

RWTH Aachen Chair

Digital Additive Production DAP

Campus-Boulevard 73

52074 Aachen

Further news

#IamDAP: Sabine Fröhlich

The Faces beyond Our Research #IamDAP: Sabine Fröhlich Sabine joined the DAP in 2020 to help building our metallographic and analytical laboratory. Leading the Metallography department, Sabine coordinates the functioning of the laboratory as well as the training of...

#IamDAP: Carsten Putz

The Faces beyond Our Research #IamDAP: Carsten Putz Carsten studied mechanical engineering at RWTH and has been part of the Digital Product Group at DAP since January 2021. Already as a student, he was passionate about cars and e-mobility, and recognized the potential...

#IamDAP: Henrik Kruse

the faces behind our research #IamDAP: Henrik Kruse Henrik is a materials scientist who joined the Digital Product group in March 2021. He has had a passion for metallic materials since his undergraduate studies at RWTH Aachen. He first encountered Additive...

#IamDAP: Sebastian Bold

the faces behind our research #IamDAP: Sebastian Bold Sebastian – Chemist and Dr. rer. nat. – is a hydrogen expert and music enthusiast. He is one of the newer members of the DAP and joined the chair in February 2022 as the new manager of the Research Area Hydrogen....

#IamDAP: Miriam Ludwigs

the faces behind our research #IamDAP: Miriam Ludwigs Miriam has a bachelor's degree in business psychology and is the group leader of the Shared Services group. Her daily businesses are finances, general administration coordinating with the marketing and...

#IamDAP: Moritz Kolter

the faces behind our research #IamDAP: Moritz Kolter Moritz has been a part of the DAP chair since February 2021. Before joining the chair, he studied mechanical engineering at TU Munich. Thematically, he examines the potential of streaming in the context of 3D...

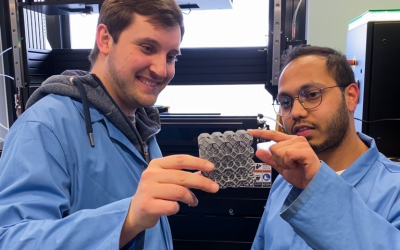

This picture shows a component that was developed in one of our projects together with Kueppers Solutions GmbH.